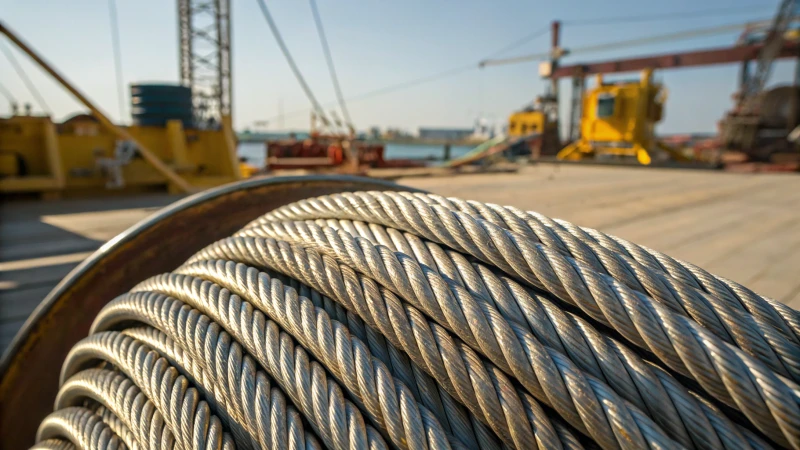

Imagine watching a crane effortlessly lift massive loads, all thanks to high-strength steel wire ropes.

High-strength steel wire ropes improve crane load performance by enhancing durability, increasing load capacity, and boosting safety. They are crucial for managing heavy and complex loads, making them vital in modern crane operations across diverse industries.

I still remember my first day on a construction site, watching cranes hoist gigantic steel beams like they were mere matchsticks. The secret behind that seemingly effortless lift? High-strength steel wire ropes. These ropes aren't just about strength—they're about reliability and precision. They carry the weight of an entire project, literally and figuratively, and knowing they're crafted with such meticulous engineering gives everyone peace of mind. Whether it's in construction, mining, or industrial manufacturing, these ropes ensure safety and efficiency, making them indispensable in today's demanding environments.

High-strength steel wire ropes increase crane load capacity.True

These ropes are engineered to bear heavier loads than traditional ropes.

High-strength steel wire ropes are less durable than standard ropes.False

They are more durable due to advanced materials and construction.

What Are the Key Features of High-Strength Steel Wire Ropes?

Imagine standing at the edge of a construction site, cranes towering above, each relying on a single unsung hero: the high-strength steel wire rope.

High-strength steel wire ropes stand out for their remarkable tensile strength, unparalleled durability, and resistance to harsh environmental conditions, making them ideal for demanding sectors like construction and mining.

I remember the first time I stood next to a massive construction crane, marveling at how such enormous machines could rely on what seemed like thin threads of steel to hoist tons of material skyward. It dawned on me just how crucial these wire ropes are, and I couldn’t help but delve deeper into their fascinating features.

Understanding Tensile Strength

I’ve always been fascinated by the strength of materials, and high-strength steel wire ropes are no exception. Their tensile strength is truly impressive, withstanding substantial tension without snapping. They typically range from 1570 to 1960 MPa, which is why they’re indispensable in heavy-duty applications like construction1 and industrial lifting.

Durability and Longevity

On one of my visits to a construction site near the ocean, I saw firsthand how environmental factors can wreak havoc on materials. Thankfully, high-strength ropes are often galvanized or coated with protective layers like PVC or nylon, effectively guarding against corrosion and wear. Take galvanized steel ropes2, for example—they’re a godsend in marine environments due to their resistance to saltwater corrosion.

Resistance to Environmental Factors

Ever wonder how these ropes withstand extreme weather? It’s all about advanced coatings and alloys. From blazing heat to biting cold, these ropes endure it all, thanks to their stainless steel variants that perform brilliantly in both humid and dry conditions.

Versatile Applications

I’ve seen these ropes in action across various industries. In construction, they’re the backbone of crane operations and heavy-lifting tasks. Mining operations also rely on them for moving hefty materials from deep underground. And let’s not forget their role in industrial settings3, like powering elevators and conveyor systems.

Wire Rope Construction

The intricate construction of these ropes always amazes me. It’s like a dance of strands twisted around a core, each configuration tailored for specific needs. Here’s a snapshot of the common types:

| Construction Type | Number of Wires per Strand | Application |

|---|---|---|

| 6x19 | 19 | General lifting |

| 6x36 | 36 | High flexibility needs |

| 8x19 | 19 | Heavy-duty lifting |

Exploring these configurations reveals how each serves different industrial requirements—a testament to their versatility and strength. It's no wonder these ropes are trusted in the most challenging environments.

High-strength steel wire ropes resist saltwater corrosion.True

Galvanized steel ropes are used in marine settings for corrosion resistance.

6x36 wire rope construction is used for general lifting.False

The 6x36 construction is used where high flexibility is needed.

How Do High-Strength Steel Ropes Improve Safety in Crane Operations?

I remember the first time I saw a massive crane in action, lifting tons of steel effortlessly. It was then I realized the unsung heroes of this feat were the high-strength steel ropes. These marvels of engineering significantly boost safety and efficiency in crane operations.

High-strength steel ropes improve crane safety by significantly enhancing load-bearing capacity, reducing the risk of breakage. Their flexibility and durability ensure they withstand wear in demanding conditions, making them a vital component in safe and efficient heavy lifting.

The Role of Load-Bearing Capacity

There was a time when I was overseeing a construction project, and we had a particularly challenging lift to execute. The weight of the beams was intimidating, but knowing our crane was equipped with high-strength steel ropes gave me peace of mind. These ropes have an exceptional load-bearing capacity4, meaning they can handle much heavier loads than traditional ones. This reliability is crucial; it minimizes the risk of rope failure, which can lead to catastrophic accidents.

| Feature | High-Strength Steel Ropes |

|---|---|

| Load Capacity | High |

| Flexibility | Moderate |

| Durability | High |

With these ropes, operators can trust their equipment to perform consistently under pressure, allowing for safer crane operations.

Flexibility and Durability

I recall a conversation with a seasoned crane operator who swore by these ropes for their perfect balance of flexibility and durability5. In dynamic work environments, cranes need to maneuver loads with precision, and these ropes make it possible. Their robust design means they endure constant friction and tension without significant wear, which is vital for long-term use.

Resistance to Environmental Factors

One winter, during a particularly harsh spell of weather, I witnessed firsthand how these ropes stood up against extreme conditions. They're engineered to resist environmental factors like severe temperatures and moisture, reducing the risk of corrosion that could compromise safety. This ensures cranes continue to operate smoothly regardless of adverse weather conditions.

Innovative Design Features

The innovative design of high-strength steel ropes is nothing short of impressive. They incorporate advanced materials and engineering techniques, enhancing their strength while minimizing stretch under load—vital for maintaining stability during lifts. If you're curious about these features, you might want to dive deeper into steel rope technology6 for more insights.

High-strength steel ropes have a higher load capacity.True

They handle heavier loads than traditional ropes, enhancing safety.

High-strength steel ropes are highly flexible.False

They offer moderate flexibility, balancing with high durability.

How Do High-Strength Steel Wire Ropes Offer Economic Benefits?

Ever wondered how a simple switch to high-strength steel wire ropes could boost your bottom line?

By opting for high-strength steel wire ropes, companies can significantly cut operational costs through enhanced efficiency, reduced downtime, and improved safety. These advantages culminate in considerable financial savings over time in industrial settings.

When I first explored the world of high-strength steel wire ropes, I was amazed by how much they could change the game for industries reliant on heavy lifting and rigorous operations.

Improved Efficiency and Load Handling

Imagine this: fewer ropes, less time, and the same hefty load smoothly lifted into place. That's exactly what high-strength steel wire ropes can do. Their impressive tensile strength means you need fewer of them to manage heavy loads, which is a total win in terms of efficiency. Picture having a smaller team accomplish the same task faster—it's like finding an extra hour in your day.

| Benefit | Description |

|---|---|

| Load Capacity | Handles heavier loads with fewer ropes |

| Efficiency | Reduces time spent in operations |

Reduced Maintenance Costs

I remember one particular project where we constantly struggled with equipment failures. Switching to high-strength ropes felt like a magic fix. Their durability means they don't wear out as quickly, leading to fewer replacements and less downtime. It's like having a car that never breaks down—less worry and more savings.

Enhanced Safety Leading to Cost Savings

Safety wasn't just a checkbox; it was our peace of mind. By reducing accident risks, high-strength steel wire ropes help lower insurance premiums and legal hassles. Plus, when everyone feels secure, productivity naturally spikes. It's the kind of positive ripple effect that any workplace could benefit from.

- Accident Risk Reduction: Fewer incidents translate to lower insurance premiums and fewer legal liabilities.

- Productivity Boost: Maintaining a safe work environment can boost productivity7, as employees feel secure using reliable equipment.

Long-Term Investment Benefits

Yes, the initial cost might raise an eyebrow, but think of it as buying quality over quantity. These ropes deliver performance that lasts way beyond their upfront price, becoming more of an investment than an expense. It's like choosing a reliable, old friend over a flashy new acquaintance—consistent and dependable in the long run.

- Longevity & Performance: While the initial investment may be higher compared to other materials, their longevity offers long-term savings8.

High-strength steel ropes reduce operational costs significantly.True

Their efficiency and durability lower maintenance and downtime expenses.

Using high-strength steel ropes increases accident rates.False

They enhance safety, reducing the risk of accidents and liabilities.

Why are high-strength steel wire ropes crucial for modern construction projects?

Remember that time you watched a massive skyscraper take shape and wondered about the invisible heroes behind the scenes?

High-strength steel wire ropes are crucial in modern construction due to their unmatched load-bearing capacity, longevity, and safety features. They ensure the seamless and secure lifting of heavy materials, essential for executing large-scale projects efficiently.

Well, it turns out those invisible heroes include high-strength steel wire ropes. I’ve always been fascinated by how these seemingly simple strands of steel can hold such tremendous weight and endure the harshest conditions. When I first stepped into the world of construction, I quickly learned that these ropes are like the unsung backbone of our industry.

Key Benefits of High-Strength Steel Wire Ropes

High-strength steel wire ropes provide exceptional load-bearing capacity, which is essential for lifting heavy materials safely. The construction of skyscrapers and bridges demands robust solutions that these ropes deliver.

| Benefit | Description |

|---|---|

| Load Capacity | Handles heavy loads efficiently |

| Durability | Resistant to wear and tear over time |

| Safety | Ensures safe lifting operations |

Material Advantages

The composition of high-strength steel wire ropes includes alloys that enhance their tensile strength. This was something I had to understand quickly, especially when cranes were working overtime in less-than-ideal weather conditions. Learn more about tensile strength9.

Applications in Construction

I’ve seen these ropes in action everywhere—from cranes towering over cityscapes to elevators whisking us up to new heights. Their ability to withstand dynamic forces makes them indispensable for construction sites where loads are continuously moved.

Innovations in Steel Wire Ropes

What really excites me is the innovation in this field. Recent advancements have introduced coatings that increase corrosion resistance, extending the lifespan of the ropes. Explore innovations in rope technology10.

Market Trends

With the rise of mega-projects globally, the demand for high-strength steel wire ropes is growing. The industry is evolving with new technologies that enhance performance while reducing costs.

| Year | Market Growth Rate |

|---|---|

| 2020 | 6% |

| 2023 | 8.2% |

As someone who loves seeing technological evolution, I find it fascinating how new advancements are pushing boundaries while keeping costs in check.

Real-World Applications

Let me share a story: during a recent urban bridge project, the reliability of these ropes was tested like never before. The whole project’s success depended on it, and thankfully, they delivered flawlessly. Case studies11 showcase how these materials facilitate complex constructions safely and efficiently.

High-strength steel wire ropes are used in skyscraper construction.True

These ropes handle heavy loads, making them ideal for skyscraper projects.

Recent advancements have decreased the corrosion resistance of ropes.False

Innovations have increased corrosion resistance, extending rope lifespan.

Conclusion

High-strength steel wire ropes enhance crane performance by increasing load capacity, durability, and safety, making them essential for efficient heavy lifting in construction and industrial applications.

-

Understanding tensile strength helps assess if these ropes can meet your project's load requirements. ↩

-

Discover why galvanized ropes are preferred in environments prone to corrosion. ↩

-

Learn about diverse industrial uses for steel wire ropes to optimize your equipment choices. ↩

-

Discover how high-load capacity ropes prevent accidents by supporting heavier loads safely. ↩

-

Learn why flexible yet durable ropes are essential for safe crane operations in various conditions. ↩

-

Explore the latest design innovations that enhance rope strength and safety in lifting tasks. ↩

-

Understand how a safe work environment increases productivity, saving costs and boosting morale. ↩

-

Discover how investing in high-strength steel wire ropes leads to substantial savings over time. ↩

-

This link provides detailed insights into the tensile strength properties of steel wire ropes, crucial for understanding their application in heavy lifting. ↩

-

Discover the latest advancements in steel wire rope coatings and materials that enhance durability and performance. ↩

-

Explore real-world examples demonstrating the application and benefits of high-strength steel wire ropes in major construction projects. ↩