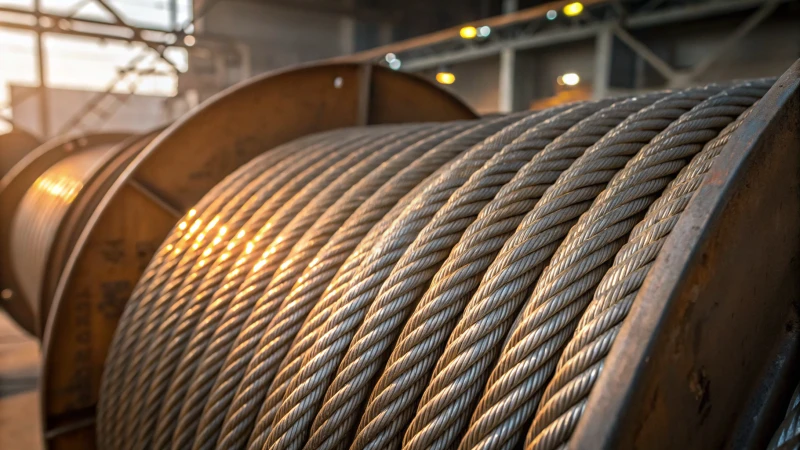

When safety is on the line, every choice matters. Steel wire ropes are the backbone of emergency systems, offering reliability when it counts most.

Steel wire ropes excel in emergency and safety systems due to their unmatched strength, durability, and adherence to stringent safety standards. Their resilience under pressure makes them indispensable for critical applications, ensuring peace of mind in high-stress scenarios.

I remember the first time I witnessed the raw power of a steel wire rope. It was during a major project where precision and safety were non-negotiable. Seeing those ropes perform flawlessly under immense stress was a revelation. This experience made me appreciate their critical role in emergency systems, where failure simply isn't an option.

Steel wire ropes aren’t just about brute strength—they’re about reliability when the stakes are high. With specifications that include high tensile strength and fatigue resistance, these ropes are built to last, often surpassing rigorous industry standards. Whether it's a high-rise crane or a life-saving pulley system, knowing that the steel wire rope will hold firm brings a sense of security that’s priceless in our line of work.

Steel wire ropes have high tensile strength.True

They are known for their ability to withstand significant stress.

Steel wire ropes are non-compliant with safety standards.False

They comply with strict safety standards, ensuring reliability.

Why Are Steel Wire Ropes So Remarkably Durable?

You ever wonder what makes those steel wire ropes so incredibly tough? They might seem just like regular wires twisted together, but there's a world of engineering magic behind their resilience.

Steel wire ropes achieve their durability through a combination of high tensile strength, corrosion resistance, and flexibility. Crafted from intertwined strands, these ropes are designed to endure heavy loads and harsh conditions, providing reliable performance in challenging environments.

The Role of Material Composition

When I first learned about steel wire ropes, I couldn't help but be impressed by the high-carbon steel they use. It’s like the Superman of materials, offering incredible tensile strength. This is essential for those big jobs like construction cranes or mining operations, where load-bearing capacity1 is non-negotiable. I've often found myself comparing this to my own work situations, where I need to rely on tools that won’t fail me under pressure.

Structural Design Enhancements

The design of these ropes reminds me of a time I watched a craftsman weave baskets—there’s an art to it. Twisting multiple strands around a core not only boosts flexibility but also adds immense strength. It’s fascinating how this design allows the ropes to absorb shocks, much like how we sometimes have to brace ourselves for life’s unexpected challenges. Curious about how they achieve this? A detailed breakdown2 can shed some light.

| Component | Material | Purpose |

|---|---|---|

| Strands | High-Carbon Steel | Provides tensile strength |

| Core | Fiber or Steel | Offers flexibility and stability |

Protective Coatings and Treatments

I remember my first big project requiring these ropes and the emphasis on their coatings—it’s not just about keeping them shiny. Coatings like PVC or galvanized finishes are critical for resisting corrosion, especially when facing the elements. Imagine being out there in a storm and knowing that your equipment won’t let you down. That's peace of mind. The importance of coatings3 is something I learned to appreciate deeply.

Fatigue Resistance and Safety Factors

Fatigue resistance in these ropes is like their secret superpower. They’re designed to handle repetitive stress without faltering. I’ve seen safety factors of at least 5:1, which reassures me that they’re built to last. Knowing this, I feel safer using them in any critical situation. Ever wondered how they test this? Fatigue testing4 is key to ensuring safety and reliability.

ISO Standards and Quality Assurance

Whenever I’m involved in procurement, one thing I always check is ISO standards compliance. It’s my way of ensuring that the products can withstand the stress and strain they’re put under. It’s like having a seal of approval that says, “Yes, you can trust this.” Discovering the impact of ISO standards5 on product reliability was a game-changer for me.

With these factors combined, steel wire ropes stand out as a testament to engineering brilliance. They’re indispensable across various industries, whether it’s construction or mining. Understanding these elements not only helps in selecting the right rope for specific needs but also gives you confidence in their unmatched durability.

Steel wire ropes are made from low-carbon steel.False

Steel wire ropes are made from high-carbon steel for tensile strength.

Protective coatings prevent corrosion in steel wire ropes.True

Coatings like PVC or galvanized layers resist moisture and chemicals.

How do steel wire ropes ensure safety compliance?

Ever wondered how steel wire ropes manage to uphold safety across industries? These seemingly simple strands of steel are crucial for maintaining the high standards we rely on daily.

Steel wire ropes meet safety standards by adhering to industry-specific regulations such as ISO 4344 and OSHA guidelines, ensuring they possess high tensile strength, fatigue resistance, and durable coatings for optimal performance in critical settings.

Understanding Safety Standards for Steel Wire Ropes

I remember the first time I stood at a construction site, gazing at a crane lifting a hefty load. It struck me how much trust we place in those steel wire ropes, silently bearing the weight of our expectations. In industries like construction, mining, and marine operations, these ropes are lifelines—literally. Compliance with safety standards isn't just a box to check; it's the backbone of our operations.

ISO 4344 outlines the essentials for lifting equipment, focusing on high tensile strength6 and fatigue resistance. This means the ropes must not only hold their ground under enormous pressure but also last through countless cycles of use without faltering. Meanwhile, OSHA regulations ensure that when we're out in the field, we're not just relying on hope but on meticulously maintained equipment. Regular inspections and adherence to these standards keep us safe and our projects on track.

Factors Contributing to Safety Compliance

-

Material Composition:

Every time I specify a steel wire rope, I'm making a choice about its material composition. Galvanized or high-carbon steel provides essential corrosion resistance and strength. Adding coatings like PVC or polyurethane isn't just an upgrade—it's a decision to extend the rope's lifespan, sometimes by 15%-20%, especially when the environment isn't playing nice.Material Type Benefits Galvanized Steel Corrosion resistance High-Carbon Steel High tensile strength Coated Ropes Extended lifespan by 15%-20% -

Safety Factors:

The safety factor is our safety net—a minimum of 5:1 gives us peace of mind that the rope can handle more than we ask of it. Whether it's an unexpected load increase or a slip in operation, this factor is our assurance against failure. -

Fatigue Testing:

Imagine a rope enduring relentless stress cycles day after day. That's what fatigue testing simulates—a relentless test of endurance that ensures these ropes can take what we throw at them without giving out when it matters most.

Technical Support and Certifications

When choosing suppliers, I always look for those who stand by their product with technical support and provide certifications confirming compliance with industry standards. Seeing those safety certifications7 is like having a seal of approval that the ropes will perform as expected.

Importance of Supplier Relationships

Building long-term relationships with suppliers isn't just good business; it's essential for consistency in product quality and delivery. Reliable suppliers who offer ongoing technical support and training help us stay ahead, keeping our teams safe and our operations smooth.

Understanding these elements helps us make informed decisions in sourcing steel wire ropes, aligning our choices with both operational needs and safety regulations. It's not just about meeting requirements—it's about ensuring everyone goes home safe at the end of the day. Dive deeper into steel wire rope standards with resources from industry experts and regulatory bodies to stay ahead of the curve.

Steel wire ropes must meet ISO 4344 standards.True

ISO 4344 sets requirements for lifting equipment, ensuring safety.

OSHA regulations don't apply to steel wire ropes.False

OSHA provides guidelines for the safe use of wire ropes in workplaces.

How do steel wire ropes ensure safety in critical systems?

Ever wondered how steel wire ropes keep us safe in everyday operations? Let me take you on a journey through their key roles in various safety systems.

Steel wire ropes are crucial for safety in elevators, cranes, and fall arrest systems. They provide essential support, ensuring operational safety by handling high loads and preventing accidents.

Applications in Elevators

Picture stepping into an elevator, trusting it to safely whisk you up to your office. It’s fascinating to think that the smooth ride is all thanks to steel wire ropes working tirelessly behind the scenes. These ropes have become the unsung heroes of elevator systems, thanks to their remarkable durability and high tensile strength8. They’re designed to handle the relentless stress of daily operations, ensuring that you get to your floor safely without a second thought.

Usage in Cranes

Back when I first saw a crane lifting massive steel beams high into the sky, I was amazed at how effortlessly those towering machines operated. The secret? Steel wire ropes. In crane operations, these ropes are the backbone of safety, meeting rigorous standards to prevent any mishaps during hoisting. High-carbon steel ropes are preferred for their strength and wear resistance9, making them perfect for handling extreme stress conditions and keeping operations smooth and safe.

Fall Arrest Systems

Imagine working on a high-rise construction site, where every step is a dance with gravity. Here, fall arrest systems are lifesavers, quite literally. Steel wire ropes in these systems are not just about support; they’re about peace of mind, knowing they’ll catch you if you slip. With additional coatings like PVC for enhanced fatigue resistance and longevity10, these ropes ensure that safety isn’t left to chance. A safety factor of at least 5:1 is generally recommended to maximize protection.

Comparative Table of Coatings

| Coating Type | Benefits |

|---|---|

| PVC | Enhances flexibility and resistance to corrosion |

| Polyurethane | Increases durability and impact resistance |

Understanding these applications helps industry professionals like me choose the right steel wire rope for enhancing safety across various systems. Whether it's for lifting heavy loads or preventing falls, steel wire ropes are indispensable, ensuring peace of mind and reliability every step of the way.

Steel wire ropes are used in elevator safety systems.True

Steel wire ropes lift and lower elevator cabins, ensuring safety.

PVC coating reduces the flexibility of steel wire ropes.False

PVC coating enhances flexibility and corrosion resistance.

Why Is Coating Important for Steel Wire Ropes?

Have you ever wondered why steel wire ropes get a coat of protection? It’s more than just a layer—it’s about endurance, safety, and cost efficiency. Dive in to uncover why coating is a game-changer for these vital tools.

Coating steel wire ropes is essential as it shields them from corrosion, abrasion, and environmental harm, extending their lifespan and performance. Using coatings like PVC or polyurethane boosts resistance to fatigue and mechanical wear, ensuring optimal durability.

I remember the first time I watched a construction project come to life—cranes towering, workers bustling, and the ever-present hum of machinery. One detail that often goes unnoticed yet plays a crucial role is the steel wire rope. But why coat them? Let me share some insights.

The Role of Coatings in Corrosion Resistance

Steel wire ropes face harsh realities: moisture, pollution, and for some unlucky ones, the salty kiss of the sea. Picture this: without a protective coating like galvanized zinc, these ropes would rust faster than a forgotten bicycle in the rain. In marine settings, where saltwater is relentless, this coating acts as a lifesaver.

| Coating Type | Protection Offered |

|---|---|

| Galvanized Zinc | Rust Prevention |

| PVC | Chemical Resistance |

| Polyurethane | Abrasion Resistance |

Enhancing Mechanical Properties

Beyond just protection, coatings enhance what these ropes can do. I once toured a mining site where polyurethane11-coated ropes were lifting tons effortlessly. These coatings keep the ropes strong and flexible, even when faced with tough conditions.

Safety Factors and Fatigue Resistance

Imagine an emergency where equipment fails because the ropes couldn’t handle repeated stress. That’s a nightmare scenario nobody wants. Coatings like PVC or polyurethane significantly improve fatigue resistance, making these ropes reliable under pressure—a fact backed by ISO 434412 standards.

Cost-Benefit Analysis

When I spoke with a procurement manager recently, they highlighted how opting for coated ropes might seem costly upfront but saves money in the long run. Less frequent replacements mean fewer delays and lower operational costs—a win-win situation if you ask me.

A detailed cost-benefit analysis13 can help procurement managers make informed decisions on whether to choose coated options based on their specific operational needs.

Choosing the Right Coating

Deciding on the perfect coating isn’t just about picking one from a lineup; it’s about understanding your needs. For chemical-heavy environments, PVC is your friend. For durability against physical wear, polyurethane has your back. It’s like choosing the right tool for the job.

In conclusion, the importance of coatings on steel wire ropes goes beyond mere protection—they ensure these ropes can perform safely and efficiently in demanding industrial applications. By understanding these benefits, you can make informed decisions that align with safety standards and operational needs.

Galvanized zinc prevents rust on steel wire ropes.True

Galvanized zinc coating creates a barrier against moisture and pollutants.

PVC coatings enhance abrasion resistance of steel ropes.False

Polyurethane, not PVC, is noted for enhancing abrasion resistance.

Conclusion

Steel wire ropes are essential for emergency and safety systems, offering unmatched strength, durability, and compliance with safety standards to ensure reliability in critical applications.

-

Learn how high-carbon steel contributes to the strength and load capacity of steel wire ropes. ↩

-

Explore how the structural design of wire ropes enhances their flexibility and strength. ↩

-

Understand how coatings protect wire ropes from corrosion and extend their lifespan. ↩

-

Find out how fatigue testing ensures the durability and reliability of steel wire ropes. ↩

-

Discover how ISO standards ensure high-quality and durable steel wire ropes. ↩

-

Learn about the benefits of high tensile strength in steel wire ropes for improved safety and performance. ↩

-

Discover essential certifications that ensure steel wire ropes meet industry safety standards. ↩

-

Discover how high tensile strength ensures elevator safety by maintaining rope integrity under stress. ↩

-

Learn why high-carbon steel is favored for its superior wear resistance in crane applications. ↩

-

Explore how coatings like PVC enhance fatigue resistance and lifespan of steel ropes. ↩

-

Explore how polyurethane coatings enhance abrasion resistance and durability in industrial applications. ↩

-

Learn about the ISO 4344 standards ensuring quality and safety compliance in steel wire rope manufacturing. ↩

-

Understand the financial implications of choosing coated steel wire ropes through a cost-benefit analysis. ↩