Ever wondered what keeps elevator wire ropes going strong despite constant use?

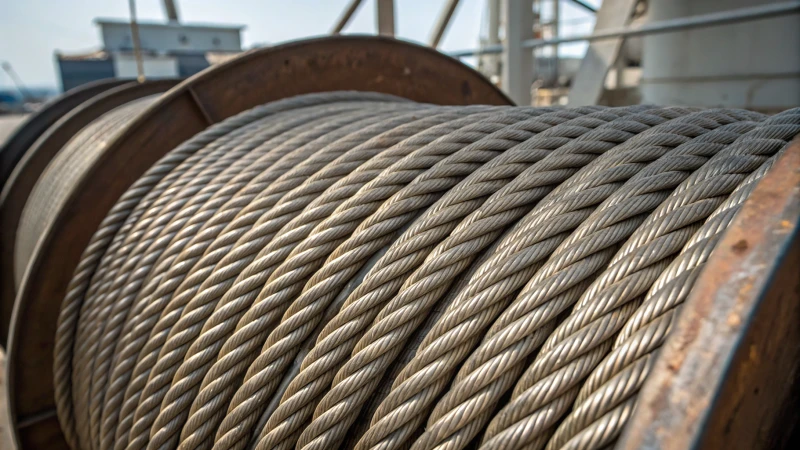

The fatigue resistance of elevator wire ropes hinges on several critical factors, including rope construction, material composition, coating, and load cycling. Ropes with higher carbon content, polymer coatings, and reinforced cores often demonstrate superior fatigue resistance, extending their lifespan significantly even under repetitive stress.

Thinking back to a bustling day at the construction site, I remember seeing those trusty elevator wire ropes at work. They handle countless trips up and down without a hitch, thanks to their thoughtful design. Let's delve into how each element contributes to their endurance.

First, consider rope construction. It's like choosing the right pair of boots for a hike—some are just better suited for the terrain. The way a rope is built affects its strength and flexibility, much like the layers in a boot provide support and grip. Then there's the material; imagine comparing a sturdy leather boot to one made of flimsy fabric. Ropes with a high carbon content are like the leather boots of the wire world—durable and reliable.

Coatings also play a role, akin to waterproofing your boots before a rainstorm. A good polymer coating shields the ropes from wear and tear. Finally, load cycling is like the miles you clock on those boots—regular use can lead to wear, but quality design minimizes fatigue.

Ropes with polymer coatings have superior fatigue resistance.True

Polymer coatings enhance durability by reducing wear and corrosion.

Higher carbon content decreases wire rope fatigue resistance.False

Higher carbon content improves strength, enhancing fatigue resistance.

How does rope construction impact fatigue resistance?

Ever wondered why some ropes outlast others under relentless stress? Let's unravel the secret behind their endurance.

Rope construction affects fatigue resistance through strand pattern, core material, and coating. Ropes with denser strands and reinforced cores generally last longer under stress, boosting their lifespan.

The Role of Strand Patterns in Fatigue Resistance

I remember the first time I encountered a complex strand pattern—it was like discovering a hidden art form within a practical tool. Strand pattern, which involves the number and arrangement of wires in a rope, is crucial to its fatigue resistance. More intricate patterns, like the 6x36, offer flexibility and strength. These patterns help reduce stress on individual wires during bending cycles, much like how a well-structured bridge distributes weight evenly.

For instance, stainless steel ropes1 with intricate strand patterns typically outperform simpler designs.

Core Materials: Reinforcement for Longevity

The choice of core material often feels like choosing the right partner—it must complement and support the strands to enhance their performance. Fiber cores provide flexibility, but steel cores are the stalwarts of strength and support. A steel core rope2 enhances fatigue resistance by ensuring even load distribution, reducing wear on the strands and extending the rope's life. I've seen this principle in action on construction sites where ropes with steel cores consistently outlast their fiber counterparts.

Impact of Coatings on Rope Durability

Coatings are like armor for ropes, shielding them from environmental damage. Zinc or polymer coatings can significantly prolong a rope's lifespan. I've witnessed firsthand how polyurethane coatings3 excel at resisting abrasion and corrosion, acting as a protective barrier against harsh elements that might otherwise lead to premature rope failure.

Comparing Fatigue Resistance Across Materials

Choosing the right material for ropes is akin to selecting the right material for a suit of armor—stainless steel ropes generally offer superior fatigue resistance compared to galvanized steel ropes, thanks to their innate corrosion resistance. Here's a simple breakdown:

| Material Type | Fatigue Resistance | Corrosion Resistance |

|---|---|---|

| Stainless Steel | High | High |

| Galvanized Steel | Moderate | Moderate |

| Fiber Core | Low | Varies |

Understanding these nuances allows us to make informed choices when selecting ropes for specific applications. Further exploration into ISO standards4 can provide even deeper insights into optimizing rope selection based on fatigue resistance, ensuring we choose the right tool for the job.

6x36 strand patterns enhance rope fatigue resistance.True

Complex strand patterns distribute stress evenly, reducing wear.

Fiber core ropes are more fatigue-resistant than steel core ropes.False

Steel cores provide better load distribution, enhancing fatigue resistance.

Why Is Material Type Crucial for Elevator Wire Ropes?

Ever wondered why the material of elevator wire ropes is so vital? It's all about safety and longevity in our daily vertical rides.

Choosing the right material for elevator wire ropes is crucial because it impacts their strength, durability, and resistance to wear and fatigue. For instance, stainless steel ropes excel in corrosion resistance and longevity, making them a top choice for humid environments.

Understanding Material Properties

I've often found myself caught up in conversations about elevator wire ropes5, especially when discussing construction projects with colleagues. There's a certain satisfaction in knowing that choosing the right material can make all the difference. Take stainless steel ropes, for example. These are my go-to when it comes to environments where humidity is a constant challenge, thanks to their superior resistance to corrosion. However, when budget constraints sneak into the conversation, galvanized ropes become an option—offering decent resistance at a fraction of the cost.

Impact on Fatigue Resistance

Fatigue resistance is something I've learned to appreciate deeply over the years, especially when dealing with machinery that endures repetitive loading. The material choice here is pivotal. Stainless steel with a higher carbon content or even polymer-coated ropes, like those with polyurethane, are fascinating because they significantly bolster fatigue resistance. I remember reading about how these materials can extend the service life by up to 40%, as per ISO 4344 standards6. It’s not just about the technical specs; it’s about ensuring safety and reducing maintenance headaches down the line.

| Material Type | Advantages | Disadvantages |

|---|---|---|

| Stainless Steel | High corrosion resistance | Higher cost |

| Galvanized Steel | Cost-effective, moderate resistance | Prone to rust in harsh conditions |

| Polymer Coated | Enhanced fatigue resistance | May require special handling |

The Role of Core Design

I remember this one time at a high-rise project where the core design of the ropes became a game-changer. We needed something robust for those incredible stress levels. Reinforced cores coupled with the right material type not only optimized safety but also boosted efficiency, which was crucial for us. It's moments like these that underline why choosing the right material isn't just a technical decision but a strategic one.

Making these choices isn't always straightforward, and it requires a deep dive into the specific needs of each application. Factors like environment and operational demands play a big role. I often find myself exploring resources on material selection for wire ropes7 to ensure I'm making the best-informed decisions possible.

Stainless steel ropes resist corrosion better than galvanized ropes.True

Stainless steel is known for its high corrosion resistance, ideal for humid environments.

Polymer coatings reduce the fatigue resistance of wire ropes.False

Polymer coatings enhance fatigue resistance by providing a protective layer.

How Do Coatings Boost Material Durability?

Have you ever wondered how a simple coating can revolutionize the lifespan of industrial materials?

Coatings enhance durability by forming a protective shield against environmental hazards, corrosion, and general wear and tear. This fortifies material longevity and ensures optimal performance in challenging settings like construction and mining.

Understanding Coating Types and Their Impact

I remember when I first encountered the magic of coatings in the field. Picture this: heavy machinery grinding away, its parts constantly exposed to abrasive forces. Enter polyurethane coatings—a game-changer offering unparalleled abrasion resistance, perfectly suited for these heavy-duty applications8. Then there's epoxy coatings; they're like the superheroes of chemical resistance, saving the day in corrosive environments where you'd think nothing could survive.

How Coatings Extend Lifespan

Think of coatings as the unsung guardians of materials. During a site visit to a mining operation, I was struck by how steel wire ropes, often battling harsh conditions, stood resilient thanks to galvanization. This simple coating allowed them to resist corrosion9, significantly prolonging their service life—a small investment for such a substantial payoff.

The Science Behind Coating Application

The secret sauce isn't just in the coating itself but also in how it's applied. Techniques like electroplating ensure every inch is covered evenly, maximizing protection. And with innovations like nano-coatings, we get enhanced protection without altering the material's properties10. It's like having your cake and eating it too!

| Coating Type | Benefits | Applications |

|---|---|---|

| Polyurethane | Abrasion resistance | Heavy machinery |

| Epoxy | Chemical resistance | Industrial equipment |

| Galvanization | Corrosion protection | Steel structures |

| Nano-coatings | Minimal weight addition, high durability | Advanced manufacturing techniques |

Understanding these different coatings is crucial, especially when you're in procurement. It's about making smart choices that enhance not just product longevity but also overall performance across industries. Choosing the right coatings can mean the difference between routine maintenance nightmares and smooth sailing operations.

Polyurethane coatings resist abrasion.True

Polyurethane coatings are known for their excellent abrasion resistance.

Nano-coatings significantly alter material weight.False

Nano-coatings offer protection without significantly altering material weight.

How Does Load Cycling Affect Wire Rope Longevity?

Ever wondered why some wire ropes seem to last forever while others fail quickly?

Load cycling impacts wire rope longevity by inducing fatigue, leading to micro-cracks and potential failure over time. Consistent stress from loading and unloading stresses the rope, but proper maintenance and selecting the right materials and construction can help mitigate these effects.

Understanding Load Cycling Impact

I still remember the first time I saw a massive crane in action on a construction site. It was a hot summer day, and I was interning at a project that seemed monumental at the time. Watching that crane lift heavy beams effortlessly was fascinating, but it also made me realize the immense stress those wires endure every day. This constant loading and unloading, known as load cycling, is a silent enemy to wire rope longevity.

In industries like construction11, mining, and marine operations, where wire ropes are the lifeline of many heavy-lifting tasks, understanding load cycling is crucial. Each cycle introduces stress, leading to fatigue over time. This fatigue isn’t just a word we toss around—it’s a serious degradation process that causes tiny cracks in the rope's strands. These cracks might be invisible at first but can grow over time, weakening the rope's structure.

Factors Influencing Fatigue Resistance

When I first learned about wire rope construction, I was surprised by how much the design can affect its durability. A 6×36 stainless steel rope is like the marathon runner of ropes—it has high fatigue resistance and can withstand repeated use better than its galvanized counterpart. This is partly due to its enhanced corrosion resistance12 and flexibility.

I’ve seen firsthand how ropes with higher carbon content or polymer coatings, like polyurethane, can extend their lifespan by up to 40%. It's fascinating how such a small change in material can make such a big difference! Ropes with reinforced core designs are also champions in high-stress applications, providing an added layer of strength.

| Rope Type | Fatigue Resistance |

|---|---|

| Stainless Steel 6×36 | High |

| Galvanized Steel | Medium |

| High Carbon Content | High |

| Polyurethane Coated | Very High |

Maintenance and Inspection Practices

One of my mentors always said, "The rope is only as good as the care you give it." Regular inspection and maintenance are non-negotiables when it comes to extending wire rope life. Spotting signs of wear early on—like broken strands or corrosion—can prevent failures that might otherwise lead to dangerous situations.

Lubrication is another aspect I’ve come to appreciate. It reduces friction between strands, keeping wear minimal during those endless cycles. Advanced testing methods, such as non-destructive testing13, offer peace of mind by detecting internal flaws invisible to the naked eye.

Mitigating Load Cycling Effects

Choosing the right rope feels like finding the perfect partner for a dance. It needs to match your rhythm—in this case, factors like load weight, frequency of use, and environmental conditions should guide your choice. Suppliers like WonBon offer a variety of ropes designed to meet rigorous safety standards14, ensuring they perform optimally under cyclic loads.

By adopting best practices in usage and maintenance, not only do we enhance the longevity of our ropes, but we also ensure compliance with industry safety regulations. Understanding and addressing load cycling impacts helps us maintain efficiency and protect both our equipment and personnel.

Load cycling causes fatigue in wire ropes.True

Repeated loading and unloading introduce stresses that lead to fatigue.

Galvanized steel ropes have higher fatigue resistance than stainless steel.False

Stainless steel ropes exhibit superior fatigue resistance due to better properties.

Conclusion

Elevator wire ropes' fatigue resistance is influenced by construction, material, coatings, and load cycling. High carbon content and polymer coatings enhance durability, ensuring safety in heavy-duty applications.

-

Explore how different strand patterns in stainless steel ropes impact their flexibility and fatigue resistance. ↩

-

Learn why steel cores enhance the strength and fatigue resistance of wire ropes. ↩

-

Discover how polyurethane coatings improve rope durability and resistance to environmental damage. ↩

-

Gain insights into standardized testing methods for evaluating rope fatigue resistance. ↩

-

This link provides insights into why selecting the right material is critical for elevator wire ropes. ↩

-

Learn more about the international standards that govern the fatigue testing of wire ropes. ↩

-

Access a comprehensive guide on selecting the right materials for wire ropes based on specific applications. ↩

-

Explore various applications of polyurethane coatings to understand how they enhance durability in different industrial settings. ↩

-

Learn about the galvanization process to understand how it provides corrosion resistance for steel structures. ↩

-

Discover the advantages of nano-coatings in improving material properties without adding weight. ↩

-

Explore how load cycling influences the wear and tear of construction equipment, helping you understand maintenance needs. ↩

-

Learn why stainless steel offers superior corrosion resistance compared to galvanized steel, enhancing rope longevity. ↩

-

Discover advanced testing techniques that detect internal flaws without damaging the wire ropes. ↩

-

Understand the safety standards governing wire ropes, ensuring compliance and safety in your operations. ↩