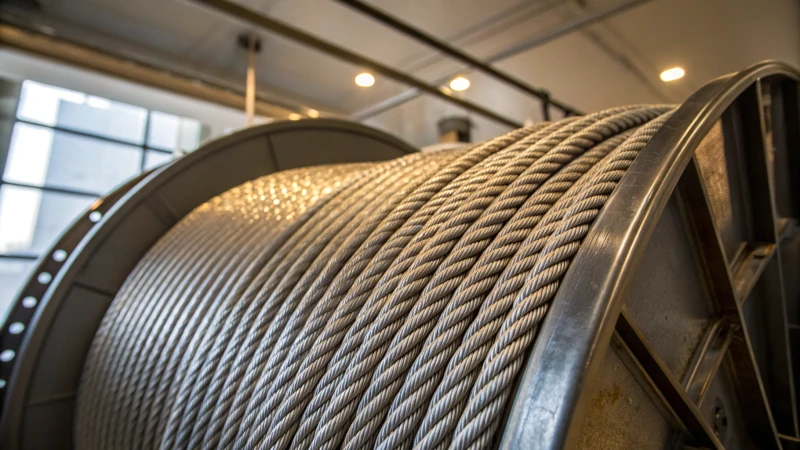

Choosing the perfect steel wire rope for elevator speed control systems isn't just about checking boxes; it's about blending safety with performance.

To select the right steel wire rope for elevator speed control, focus on ropes that offer a balance of flexibility, load-bearing strength, and wear resistance. Consider multi-layer constructions or polymer coatings for improved performance and durability.

Once, while managing a project in a bustling city, I faced the daunting task of selecting the ideal wire rope for our elevator systems. The stakes were high—not just for functionality, but for ensuring the safety of countless users. I learned that understanding different rope constructions, like 7×19 or 6×37, can make a world of difference in dynamic environments. These types offer the flexibility and strength needed to endure rapid movements and load changes. It's like finding the perfect running shoe that supports your stride without compromising comfort.

And don't underestimate the value of multi-layered constructions or polymer coatings—they're like the secret sauce for longevity, especially when you’re aiming for enhanced performance. These features can boost dynamic capabilities by up to 20%, according to ISO standards. So, when you're in the thick of procurement decisions, think beyond the specs—imagine the impact on everyday use. That's what truly guides the best choice.

Polymer-coated ropes enhance elevator performance.True

Polymer coatings improve dynamic performance and longevity of ropes.

Single-layer ropes are best for elevators.False

Multi-layer constructions offer better flexibility and load capacity.

What should you know about elevator wire rope specifications?

Ever wondered what goes into the backbone of an elevator's smooth ride? Let's dive into the specs that make elevator wire ropes tick.

Key specifications for elevator wire ropes include tensile strength, construction type, diameter, and material composition. These factors ensure the ropes can handle loads while providing flexibility and durability, essential for safe and efficient elevator operation.

Diving into the Details of Elevator Wire Ropes

When I first started digging into the world of elevator wire ropes, I was amazed at how intricate and crucial these components are. It was like discovering the hidden backbone of those smooth rides we often take for granted.

Tensile Strength and Material Composition

Imagine an elevator carrying a load up to the 50th floor without a hitch. The tensile strength of the wire ropes is what makes this possible. It's all about the maximum stress the rope can take before saying, "Nope, not today!" High-carbon steel is often the go-to choice here because it packs a punch in terms of strength and durability1. It's like having a safety net that you can trust every single time.

Plus, there's the battle against the elements. Ever seen a rope that's had a few too many run-ins with rain or humidity? Galvanized or stainless steel ropes are lifesavers in such environments, warding off rust like a pro and extending their lifespan far beyond what you'd expect.

Construction Type: Understanding Configurations

The artistry of these ropes lies in their construction. When I learned about configurations like 7×19 or 6×37, it felt like peering into an engineer's playbook. These setups offer a sweet spot between flexibility and load-bearing capacity, crucial for those start-stop cycles typical in elevators.

Here's a handy table to sum it up:

| Configuration | Flexibility | Load Capacity | Best Use Cases |

|---|---|---|---|

| 7×19 | High | Moderate | General-purpose, elevators |

| 6×37 | Very High | High | Heavy-duty, high-rise elevators |

Choosing the right one boils down to what your specific project demands and project requirements2.

Diameter and Coating Options

Now, let's talk diameter. It's not just about thickness; it's about finding that balance between weight support and flexibility. For most standard systems, something between 8mm to 13mm does the trick.

And then there's polymer coating—it's like giving the ropes a superhero cape. These coatings enhance abrasion resistance and can boost dynamic performance by up to 20%. Think of them as the unsung heroes in modern elevator designs3.

Importance of Compliance with Standards

Finally, compliance is key. These ropes need to dance to the tune of international standards like ISO 4344 to ensure they're up to par on safety and performance fronts. It's not just about ticking boxes; it's about ensuring peace of mind for everyone who steps into an elevator.

By paying attention to these specifications, decision-makers like us can ensure our elevator systems are safe and efficient. After all, it's these details that keep the world moving smoothly, one floor at a time.

High-carbon steel is used for elevator wire ropes.True

High-carbon steel offers superior strength and durability for elevator ropes.

Polymer coatings decrease rope abrasion resistance by 20%.False

Polymer coatings enhance, not decrease, abrasion resistance by up to 20%.

How Does Construction Type Affect Rope Performance?

Ever wondered why some ropes just seem to handle everything you throw at them while others don’t quite make the cut?

Rope performance is shaped by construction type, which affects flexibility, strength, and durability. For instance, 7x19 ropes are incredibly flexible and durable, making them perfect for dynamic uses like cranes.

Understanding Rope Construction Types

Let's dive into the world of ropes. If you're anything like me, you've probably marveled at how some ropes are built to endure the toughest conditions. I've spent countless hours trying to pick the right one for my projects, knowing that not all ropes are created equal.

Ropes come in different construction patterns like 6x19, 6x37, and 7x19. Each of these has its special place in our toolkits:

- 6x19 Construction: This is your go-to for strength and abrasion resistance. I remember using this type when I needed something reliable for heavy lifting.

- 7x19 Construction: Flexibility is the name of the game here. I once used it for a project involving cranes, and it was a game-changer4.

- 6x37 Construction: A happy medium between flexibility and abrasion resistance. It's been my choice for tasks that require just the right balance.

Flexibility vs. Strength

In the world of ropes, it's often a trade-off between flexibility and strength. I recall a time when I had to choose a rope for a project with dynamic movements. The 7x19, despite its moderate load-bearing capacity, made handling so much smoother.

| Construction Type | Flexibility | Strength |

|---|---|---|

| 6x19 | Moderate | High |

| 7x19 | High | Moderate |

| 6x37 | Medium | Medium |

Material Considerations

Material matters just as much as construction. From my experience, choosing the right material can make or break your project:

- Stainless Steel: Perfect for corrosive environments like those near the sea. It's saved my projects from rust more than once.

- Galvanized Steel: A budget-friendly option that doesn't compromise much on durability.

- Polymer-Coated Ropes: When I need something to last under harsh conditions, these are my go-to.

Applications in High-Stress Environments

In high-stress settings like mining or construction, I've seen firsthand how crucial it is to get the right rope. A friend once shared how switching to a multi-layer construction rope improved performance significantly in their mining operations. Research supports this, showing up to a 20% performance boost with polymer coatings as noted in recent studies5.

To get even deeper into the specifics of what makes one rope better than another, checking out resources on rope specifications6 has always provided me with the insights needed to make informed choices.

6x19 ropes are ideal for dynamic applications.False

6x19 ropes are better suited for general lifting, not dynamic uses.

Stainless steel ropes resist corrosion in marine environments.True

Stainless steel offers high corrosion resistance, ideal for marine use.

Why is corrosion resistance important in elevator systems?

Ever wondered why some elevators seem to last forever while others are constantly breaking down? It all comes down to one thing: corrosion resistance.

Corrosion resistance is crucial in elevator systems to prevent metal deterioration, maintain structural integrity, and lower maintenance costs. By shielding key components from environmental harm, it ensures safety and dependability.

Understanding Corrosion in Elevators

Let me take you back to a time when I first learned about the insidious nature of corrosion. I was overseeing a project where the elevator systems were failing faster than a toddler's patience in a long checkout line. The culprit? Corrosion! Moisture and salts had turned once-strong metals into brittle shadows of their former selves. In elevator systems7, this deterioration can lead to frayed cables, rusted panels, and compromised safety mechanisms—real-life nightmares for anyone relying on them daily.

The Impact on Structural Integrity

You know, it's amazing how something as small as a speck of rust can undermine something as significant as an elevator's structural integrity. Elevators are made up of various metallic components—cables, shafts, gears—each critical for their smooth operation and safety. If corrosion sneaks in, these components can weaken significantly. Just think of it like a slow leak in a tire; if not addressed early, it leads to disaster. Regular inspections might not always catch corrosion early, so using resistant materials is like giving your elevator an extra layer of armor.

| Component | Potential Issues Due to Corrosion | Solutions |

|---|---|---|

| Cables | Fraying and breakage | Use stainless steel or coated cables |

| Panels | Rust and aesthetic degradation | Apply protective coatings |

| Shafts | Compromised load-bearing capacity | Utilize galvanization techniques |

Cost Implications of Corrosion Damage

Addressing corrosion damage is like dealing with a leaky roof—you either spend on repairs now or risk a hefty replacement bill later. Trust me, I've learned this the hard way with elevators. Expensive repairs and downtime disrupt operations and inconvenience everyone involved. Opting for corrosion-resistant materials8 from the start can save a lot of headaches by extending the lifespan of elevator systems and slashing maintenance needs.

Enhancing Safety Standards

Safety isn't just a priority; it's a way of life, especially when it comes to elevators. Corrosion resistance plays a pivotal role in maintaining elevator safety. It's like giving your elevator an invisible shield against environmental hazards. This becomes crucial in high humidity or pollution areas, where corrosion risks are elevated. By ensuring critical components remain protected, manufacturers can make sure elevators meet safety standards9.

Innovations in Corrosion-Resistant Materials

The world of materials science is always evolving, bringing us innovations that make elevators more robust than ever before. The development of advanced alloys and coatings means we've got some serious tools in our toolbox. For example, polymer coatings10 offer excellent protection against moisture ingress without compromising mechanical performance. These innovations are game-changers for anyone, like me, who wants to deliver reliable elevator systems that stand the test of time.

Corrosion weakens elevator cables, risking safety.True

Corrosion can cause fraying and breakage of elevator cables, compromising safety.

Elevator panels are immune to rust without coatings.False

Without protective coatings, elevator panels can rust and degrade aesthetically.

Which Industry Standards Should You Consider?

Navigating industry standards can feel like a maze, but finding the right ones can revolutionize your business's efficiency and credibility.

When considering industry standards, look at ISO 9001 for quality management, ISO 45001 for health and safety, and ISO 14001 for environmental management. These standards ensure quality, safety, and sustainability in your operations.

Key Industry Standards to Consider

When I first ventured into understanding industry standards, it was like diving into a vast ocean of regulations and benchmarks. However, I quickly realized how crucial they are for aligning operations with global best practices. The ISO 9001 standard is a beacon for quality management, helping businesses consistently meet customer needs while streamlining efficiency. If your focus is on health and safety, the ISO 45001 framework is invaluable for enhancing worker safety and minimizing workplace risks.

| Standard | Purpose |

|---|---|

| ISO 9001 | Quality Management |

| ISO 45001 | Occupational Health & Safety |

| ISO 14001 | Environmental Management |

Environmental and Safety Standards

For those of us working in sectors where environmental impact is a concern, the ISO 14001 standard offers a roadmap for improving environmental performance. I remember a project where adopting this standard led to more efficient resource use and significant waste reduction. In industries like construction or heavy machinery, adhering to American National Standards Institute (ANSI) regulations11 can ensure safety compliance for machinery and operational processes.

Sector-Specific Standards

Every sector has its own unique set of standards to adhere to. In construction, for example, ASTM International standards ensure materials are up to par in strength and durability. My tech-savvy friends in IT swear by ISO/IEC 27001 for keeping information secure.

Determining which standards to follow means assessing your business's specific needs and potential risks. While some standards, like ISO 9001, are broadly applicable, others target niche markets. For instance, if you're in the automotive field, the IATF 16949 standard is pivotal for quality management in automotive production.

Learn more about ISO standards12 to pinpoint those that align with your business goals. Embracing these standards not only boosts your credibility but also enhances operational efficiency and ensures compliance with legal regulations.

ISO 9001 is only applicable to manufacturing industries.False

ISO 9001 is applicable across various industries, not just manufacturing.

ISO 45001 focuses on improving workplace safety.True

ISO 45001 provides a framework to improve worker safety and reduce risks.

Conclusion

Selecting the right steel wire rope for elevator speed control involves balancing flexibility, strength, and durability, with multi-layer constructions and polymer coatings enhancing performance and safety.

-

Discover how material choices impact the durability and lifespan of elevator wire ropes. ↩

-

Learn how different wire rope configurations can cater to specific project requirements. ↩

-

Explore features that modernize elevator systems for improved performance and safety. ↩

-

Explore why 7x19 construction is preferred for its flexibility in dynamic environments like cranes and elevators. ↩

-

Learn about studies showing how polymer coatings enhance rope durability and performance. ↩

-

Find comprehensive specifications that can guide you in selecting the appropriate rope type for your project. ↩

-

Discover how corrosion affects different components of elevator systems. ↩

-

Understand the cost-saving benefits of using corrosion-resistant materials. ↩

-

Explore how corrosion resistance influences compliance with safety standards. ↩

-

Stay informed about recent innovations in materials for corrosion prevention. ↩

-

Learn about ANSI safety requirements to ensure compliance in machinery operation. ↩

-

Explore various ISO standards to find those relevant to your industry needs. ↩