Have you ever wondered how to keep elevator steel wire ropes in top shape?

The best anti-corrosion treatments for elevator steel wire ropes include galvanization and polymer coatings like PVC or polyurethane. These methods significantly extend the ropes' lifespan by providing robust protection against environmental factors that cause rust and degradation.

I remember the first time I had to deal with elevator maintenance—it was a nerve-wracking experience, especially when I learned about the importance of protecting steel wire ropes from corrosion. Galvanization and polymer coatings emerged as lifesavers, providing that extra layer of security I desperately needed. These treatments not only extend the lifespan of the ropes but also ensure safety and reliability. It was reassuring to know that with the right protection, the chances of unexpected failures drastically drop, making both daily operations and long-term maintenance a lot smoother. Let me guide you through these treatments and help you make the best choice for your needs.

Galvanization extends elevator ropes' lifespan by 50%.True

Galvanization provides a zinc coating that protects against rust, extending lifespan.

Polymer coatings are ineffective for preventing rope corrosion.False

Polymer coatings like PVC provide a barrier against moisture, preventing corrosion.

How Does Galvanization Protect Elevator Steel Wire Ropes?

Have you ever wondered how elevator ropes defy rust and wear?

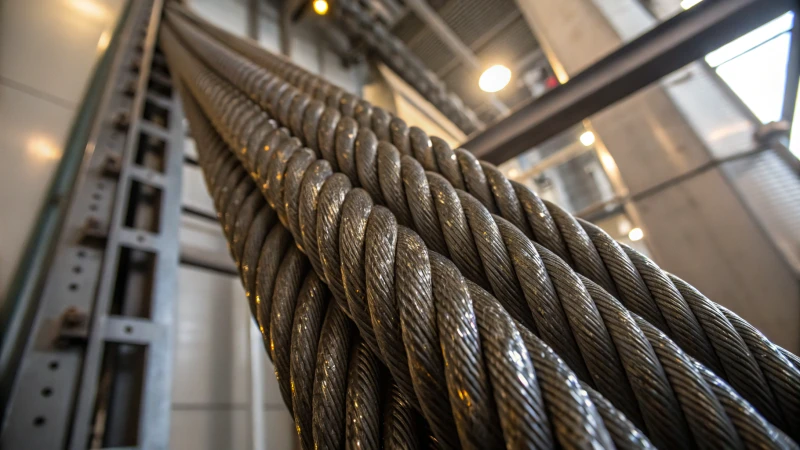

Galvanization protects elevator steel wire ropes by coating them with zinc, which acts as a barrier against corrosion. This protective layer enhances the ropes' durability, ensuring longevity and reliable performance in challenging environments.

Growing up, I always found elevators fascinating. Their silent, relentless up-and-down journeys seemed almost magical. Years later, I discovered the secret behind their steadfast reliability—galvanization. Imagine it like the armor on a medieval knight, only this time, it's a zinc coating shielding the steel ropes from corrosion.

The Role of Zinc in Galvanization

Galvanization is essentially like giving steel ropes a suit of armor. This process involves applying a thin layer of zinc to the surface of the ropes. Not only does this create a physical barrier against moisture and corrosive agents, but it also provides cathodic protection. It’s as if zinc is the self-sacrificing hero; when the coating gets scratched or damaged, zinc corrodes instead of the steel beneath it.

Benefits in Humid and Saline Environments

I remember once walking along a beach, noticing how the salty air seemed to corrode everything in its path—except for those perfectly operational elevators at the beachfront hotel. The secret? Galvanized steel wire ropes. In humid or saline environments, these ropes significantly outlive their uncoated cousins.

| Environment Type | Galvanized Rope Longevity | Untreated Rope Longevity |

|---|---|---|

| Humid | 5-10 years | 2-3 years |

| Saline | 4-7 years | 1-2 years |

Comparative Analysis: Galvanized vs. Polymer-Coated Ropes

Picture this: combining galvanization with a polymer coating is like upgrading from a single-layer raincoat to a fully insulated jacket. While galvanization alone offers solid protection, adding a polymer layer such as polyurethane extends the rope's life by an additional 15%-20%. This combo is especially beneficial in marine environments.

- Galvanized Only: Solid corrosion resistance but may require more frequent inspections.

- Polymer-Coated & Galvanized: Enhanced protection, reducing maintenance frequency and costs.

Real-World Applications and Standards

According to ASTM A475 standards, galvanized ropes are recommended for elevators due to their strength and corrosion resistance balance. Industries like construction and mining often choose these ropes for their ability to perform under stress. Understanding these standards helps procurement managers make informed decisions about steel rope selections1. Whether you’re sourcing ropes for high-rise buildings or deep underground operations, ensuring quality and longevity through galvanization is key.

Galvanization uses zinc to prevent steel rope corrosion.True

Zinc acts as a protective barrier and offers cathodic protection.

Polymer coatings reduce the need for galvanized ropes.False

Polymer coatings enhance protection but do not replace galvanization.

What Are the Benefits of Using Polymer Coatings?

Ever wondered how some materials withstand the harshest conditions while looking sleek and new?

Polymer coatings provide superior corrosion resistance, enhanced abrasion protection, and aesthetic customization. Ideal for extending the lifespan of materials in challenging environments, these coatings are versatile across industries from construction to textiles, offering both durability and flexibility.

Enhanced Corrosion Resistance

I remember standing on a pier once, mesmerized by the towering ships and their massive steel ropes. The salty air seemed thick enough to taste, reminding me of how brutal the sea can be on anything unprotected. It's no surprise then, that polymer coatings like polyurethane are a game-changer here. They form a robust barrier that keeps moisture and chemicals at bay, preserving the integrity of materials in marine or industrial settings. Imagine elevator ropes withstanding salty breezes and lasting three times longer than uncoated ones—now that's impressive!

For example, elevator ropes coated with polyurethane have shown increased longevity of up to 300% compared to uncoated alternatives in saline conditions. This makes them a preferred choice for industries exposed to harsh weather conditions.

Abrasion and Impact Protection

Back when I worked near mining operations, I'd see machinery relentlessly churn through mountains, day in and day out. Watching those machines made me appreciate the unsung heroism of polymer coatings. Applied to steel ropes, these coatings absorb impacts and reduce wear and tear, keeping everything running smoothly with fewer breakdowns. It's like having an invisible shield that makes sure you get the most out of your equipment while keeping maintenance woes at bay.

Consider mining equipment, where coated steel ropes endure heavy loads and harsh conditions. The abrasion resistance2 of polymers ensures these ropes remain operational longer, reducing downtime and maintenance costs.

Aesthetic Enhancement and Customization

I once participated in a community project that involved sprucing up an old bridge. We opted for polymer coatings in vibrant hues to protect against rust and add a splash of color. It's amazing how a simple coating can transform dull, lifeless steel into something so visually stunning without compromising on strength.

In construction, using colored polymer coatings on steel structures not only protects against rust but also enhances the visual appeal of buildings or bridges. This aesthetic flexibility is valuable for projects where appearance is as important as durability.

Flexibility and Adaptability

Polymer coatings remind me of those Swiss Army knives—versatile and always up for a challenge. Whether it's metals, plastics, or textiles, these coatings adapt like a pro. Need something to withstand high temperatures or chemical exposure? You can customize them to meet those exact requirements. This adaptability is a boon for automotive applications where engine components must endure heat.

The ability to tailor these coatings to specific needs, such as temperature resistance or chemical protection, allows for customized solutions that address unique challenges across sectors. For instance, heat-resistant polymers3 are critical in automotive applications where engine components are exposed to high temperatures.

| Property | Polymer Coating | Benefit |

|---|---|---|

| Corrosion Resistance | High | Longevity in marine environments |

| Abrasion Resistance | Superior | Reduced maintenance costs |

| Aesthetic Options | Varied | Customizable appearance |

| Flexibility | Excellent | Versatile across applications |

These benefits underscore why polymer coatings are increasingly becoming a go-to solution for enhancing material performance across diverse industries. They offer a combination of protection, aesthetics, and flexibility that traditional coatings may lack.

Polymer coatings improve corrosion resistance by 300%.True

Polyurethane-coated elevator ropes last up to 300% longer in saline conditions.

Polymer coatings are only suitable for metal surfaces.False

They can be applied to metals, plastics, textiles, and more.

How Do Environmental Conditions Affect Corrosion Resistance?

Have you ever watched a shiny metal slowly rust away, wondering what invisible forces are at play?

Environmental conditions like humidity, salinity, and temperature profoundly impact corrosion resistance by accelerating electrochemical reactions. High humidity boosts moisture content, while saline settings enhance ionic activity, both leading to faster material degradation.

Humidity and Its Impact on Corrosion

Humidity is more than just a frizzy hair culprit; it's a silent force in corrosion. Back when I lived near the ocean, I saw firsthand how high humidity could turn a well-maintained steel fence into a rusty spectacle. Moisture acts as an electrolyte, setting the stage for electrochemical reactions that speed up corrosion. Those living in coastal areas know this all too well—our outdoor furniture often needed extra coatings or frequent replacements to fend off the relentless sea air. This moisture acts as an electrolyte, enabling the flow of electrons and ions that accelerate the corrosion process4.

The Role of Salinity in Corrosion Resistance

Saline environments are like a perfect storm for corrosion. Think of all those boats and marine equipment constantly battling rust due to aggressive chloride ions in saltwater. When I worked on a project near the docks, we had to select materials that could endure this harshness. Stainless steel and polymer-coated options became our go-to for their superior durability against saltwater's pitting and localized corrosion.

Using materials with higher resistance, such as stainless steel or those with polymer coatings5, can enhance durability in these settings.

| Environmental Factor | Effect on Corrosion |

|---|---|

| Humidity | Increases moisture content, enhancing electrochemical reactions |

| Salinity | Introduces chloride ions that accelerate metal degradation |

| Temperature | Higher temperatures increase reaction rates |

Temperature's Influence on Corrosion Rate

Temperature can be a sneaky culprit in speeding up corrosion. I recall a summer when the heat seemed to make everything deteriorate faster—metal tools left in the sun seemed to age overnight. Higher temperatures crank up the rate of chemical reactions, including those causing corrosion. For industries running equipment at high temperatures, choosing materials with exceptional thermal stability6 is non-negotiable to avoid rapid wear and tear.

pH Levels and Corrosive Environments

Lastly, pH levels can dramatically shift the corrosion landscape. I once worked with a team assessing equipment in an acidic environment, and we learned quickly how low pH could ravage materials. Acidic conditions invite increased hydrogen ion concentration, accelerating corrosion, while alkaline conditions might slow it down but bring about different issues like stress corrosion cracking. Thoroughly understanding local pH conditions7 is crucial when selecting materials for construction or manufacturing projects.

High humidity accelerates corrosion processes.True

Moisture in high humidity acts as an electrolyte, facilitating corrosion.

Alkaline conditions always prevent corrosion.False

Alkaline conditions may reduce some corrosion but cause stress cracking.

How Can We Maximize the Lifespan of Elevator Ropes?

Ever wondered what keeps elevator ropes ticking longer? Well, I did too, and it turns out the secret lies in the right treatment.

Polyurethane coatings are the go-to solution for maximizing the lifespan of elevator ropes, offering superior corrosion resistance and durability across diverse environments.

The Role of Coatings in Enhancing Rope Longevity

I remember the first time I had to decide on a treatment for elevator ropes—it felt like trying to crack an ancient code. Elevator ropes face constant wear and tear, and protecting them is crucial. That's where coatings come into play. Galvanization gives ropes a zinc shield, warding off corrosion. This is especially handy in humid or salty settings, where zinc layers of 25 to 35 μm add years to the ropes' lives.

However, when I discovered polyurethane coatings, it was like finding a hidden treasure map. These coatings offer an extra layer of defense, boosting corrosion resistance by 15%-20% more than galvanized alone. Studies, such as those from ASTM A4758, show that in harsh marine conditions, ropes with polyurethane can last up to 300% longer than untreated ones.

| Coating Type | Corrosion Resistance | Lifespan Increase |

|---|---|---|

| Zinc (Galvanized) | Medium | 5-10 years |

| Polyurethane | High | 15%-20% more |

Environmental Factors Impacting Rope Lifespan

When I think about elevator ropes in different environments, it's like imagining them as superheroes battling the elements. In marine environments, they need to withstand salty air. Meanwhile, in urban areas, pollution can be the enemy. Polymer coatings are like a superhero suit, offering a non-reactive shield against these threats, which is why they're often the top choice for safeguarding investments in elevator maintenance.

Maintenance and Regular Inspections

Choosing the right coating is just one part of the equation. Regular inspections and maintenance are just as vital. It's like going to the doctor for a regular check-up—you catch issues before they become big problems. By routinely checking the ropes' condition, we can avoid sudden failures and extend their usability.

For maintenance professionals, understanding the type of treatment and its expected lifespan9 helps in planning and budgeting for replacements or upgrades. This knowledge ensures safety and compliance with standards.

By considering these factors, procurement managers like John or Emma can make informed choices about treatments that offer both safety and cost-effectiveness. Plus, suppliers providing technical support can guide us in selecting treatments best suited to our operational needs.

Polyurethane coatings increase rope lifespan by 300% in marine environments.True

Polyurethane coatings enhance durability significantly over untreated ropes in marine settings.

Galvanized ropes offer the highest corrosion resistance available.False

Polyurethane coatings provide higher corrosion resistance than galvanized ropes.

Conclusion

Galvanization and polymer coatings, like polyurethane, are the best anti-corrosion treatments for elevator steel wire ropes, significantly enhancing their lifespan and durability against environmental factors.

-

Explore the ASTM A475 standards to understand requirements for galvanized wire ropes in industrial applications. ↩

-

Exploring this link will reveal how abrasion-resistant coatings can enhance durability and reduce maintenance costs across various industries. ↩

-

This link will show how heat-resistant polymers are used in industries like automotive to improve safety and performance. ↩

-

Learn how varying humidity levels influence the corrosion process and what materials are more resistant. ↩

-

Discover which materials are most suitable for use in high-salinity conditions to prevent corrosion. ↩

-

Explore how temperature variations impact metal corrosion rates and material stability. ↩

-

Understand how different pH levels affect metal corrosion and what protective measures can be implemented. ↩

-

Explore ASTM A475 standards to understand how polyurethane coatings enhance elevator rope longevity by offering superior corrosion resistance compared to untreated options. ↩

-

Discover practical maintenance tips to extend elevator rope lifespan, ensuring cost-effective operation while adhering to safety regulations. ↩