Ever wondered why steel wire ropes are the go-to for elevators? It's not just about strength.

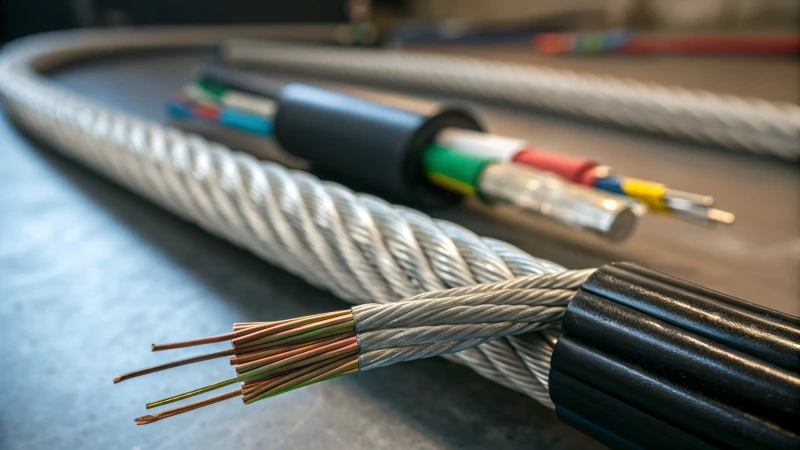

Steel wire ropes stand out in elevator systems because of their exceptional tensile strength and durability, perfectly suited for high dynamic loads. Unlike fiber optic and polymer cables, which excel in communication, steel wire ropes are specifically designed for lifting tasks, making them indispensable in vertical transport.

I remember the first time I realized the importance of choosing the right cable for an elevator system. It was during a project where we were evaluating materials, and the decision felt monumental. Steel wire ropes emerged as the clear choice due to their sheer strength and ability to handle heavy loads without a hiccup. But it wasn’t just about lifting; it was also about ensuring that every ride felt safe and smooth.

While steel wire ropes dominate in lifting, understanding the complementary role of other cable types is key. Fiber optic cables, for instance, are brilliant for elevator communication systems, ensuring signals travel long distances without losing clarity—perfect for those towering skyscrapers. And then there are polymer cables, flexible and resilient, often playing a supporting role in these complex systems. The synergy between these different cables keeps everything running like clockwork.

Steel wire ropes are ideal for vertical lifting in elevators.True

Steel wire ropes offer superior tensile strength, essential for lifting.

Fiber optic cables are used for lifting in elevator systems.False

Fiber optic cables are used for communication, not lifting.

Why Are Steel Wire Ropes Preferred for Elevators?

Ever thought about what keeps elevators safely gliding up and down those towering buildings? It's all about the strength and reliability of steel wire ropes. Let's dive into why they are the go-to choice for elevators.

Steel wire ropes are preferred for elevators because they offer exceptional tensile strength, durability, and dynamic load handling. These qualities ensure safety and efficiency in vertical lifting, making them essential for modern elevator systems.

The Strength Factor

I remember the first time I stepped into an elevator as a kid, feeling a mix of excitement and a bit of apprehension. Little did I know then that the secret to that smooth ride was the steel wire ropes working tirelessly behind the scenes. Their incredible tensile strength is like having a team of superheroes hoisting you up effortlessly. Made by twisting multiple strands of steel together, these ropes are built to last and handle the heaviest loads without breaking a sweat.

| Property | Steel Wire Ropes | Fiber Optic Cables | Polymer Cables |

|---|---|---|---|

| Tensile Strength | High | Low | Moderate |

| Durability | High | Moderate | High |

| Flexibility | Moderate | High | Very High |

Durability and Longevity

I once had a friend who worked in building maintenance, and he always marveled at how steel wire ropes withstand the relentless wear and tear in elevator shafts. Their robustness and resistance to corrosion1 mean they keep performing, rain or shine, ensuring a longer life than other materials might offer. It's like owning a car that just never breaks down.

Handling Dynamic Loads

Elevators don't just lift; they manage dynamic loads gracefully as they transport people and goods. It's a bit like dancing, with steel wire ropes leading the way—always in control, always on beat. Their unique construction provides just the right balance of strength and flexibility, ensuring smooth rides without the hiccups of unexpected breakdowns2.

Safety and Compliance

Safety in elevators is non-negotiable. I think of it like this: when you're entrusting your safety to machinery, you'd want something that complies with all the right standards. Steel wire ropes rise to this challenge, meeting rigorous safety requirements and providing peace of mind. It's reassuring to know that whether you're scaling a skyscraper or just heading to your office on the 15th floor, these ropes have got your back.

- Safety Compliance: These ropes are trusted worldwide because they meet stringent international safety standards.

- Load Testing: Regular checks ensure that these ropes can handle whatever comes their way, keeping you safe at every ride.

To delve deeper into how these mighty steel wires contribute to elevator safety, check out more on elevator safety3.

Steel wire ropes have higher tensile strength than polymer cables.True

Steel wire ropes offer high tensile strength, superior to polymer cables.

Fiber optic cables are more durable than steel wire ropes in elevators.False

Steel wire ropes are more durable than fiber optic cables in elevator use.

How Do Fiber Optic Cables Revolutionize Modern Elevators?

Imagine stepping into an elevator that's not just a box moving up and down but a smart, connected space enhancing our daily journeys.

Fiber optic cables in elevators ensure quick and reliable data transmission, supporting crucial functions like remote diagnostics, video surveillance, and internet connectivity. These advanced systems are essential for the seamless operation of modern high-rise buildings.

When I first heard about fiber optic cables transforming elevator technology, I was intrigued. It's not just about getting from floor to floor anymore; it's about creating a smart, efficient space that anticipates our needs. Think about it: these cables transmit data at lightning speed, enabling real-time monitoring4 and control systems. This high-speed capability is particularly vital in our era of smart buildings.

Advantages of Fiber Optic Cables in Elevators

Imagine living in a skyscraper where the elevator seamlessly communicates with every system in the building. Fiber optic cables make this possible by transmitting vast amounts of data without interference. This means more reliable connections for everything from video feeds to internet connectivity.

| Feature | Traditional Cables | Fiber Optic Cables |

|---|---|---|

| Data Transmission Speed | Moderate | High |

| Signal Degradation | High over distance | Low |

| Installation Flexibility | Limited | High |

Fiber Optics and Elevator Communication

Remember the times when you tried to make a call in an elevator, and it cut out? Fiber optics change all that by ensuring continuous communication between floors and the control room. They're like the unsung heroes of safety and efficiency, making sure everything from emergency alerts to video intercoms5 runs smoothly.

Role in Emergency Systems

In emergencies, staying connected can mean everything. I can't help but feel reassured knowing that fiber optic cables support uninterrupted communication, even when power is out. This reliability is a game-changer for emergency response teams and passenger safety.

Future Prospects

As technology advances, fiber optics are paving the way for even more innovations in building management. Picture automated maintenance alerts and enhanced security measures becoming the norm. It's exciting to think about how these developments will continue to shape our experiences in high-rise living.

Fiber optics improve elevator safety.True

Fiber optics enable reliable communication systems essential for safety.

Traditional cables transmit data faster than fiber optics.False

Fiber optics offer higher data transmission speeds than traditional cables.

Why Choose Polymer Cables for Elevators?

Ever wondered how polymer cables are reshaping the elevator industry? Let me take you on a journey through their benefits, which extend far beyond just moving people between floors.

Polymer cables in elevator systems bring enhanced flexibility, reduced weight, and greater resilience to environmental factors. These benefits translate to smoother rides, less wear on parts, and better energy efficiency, making them a smart alternative to traditional steel wire ropes.

Advantages of Polymer Cables in Elevators

I remember the first time I learned about polymer cables—it was during a project where we needed a solution to reduce the constant wear and tear on elevator components. Their flexibility truly amazed me, allowing for smoother operations and reducing mechanical stress on the system. This not only made the elevators last longer but also meant fewer maintenance headaches down the line.

One of the biggest surprises was how light these cables were. Compared to the hefty steel ropes we were used to, polymer cables are a breeze to handle. This lightweight nature doesn’t just make installation easier; it also reduces the load on motors and supporting structures. I was thrilled when we noticed the energy savings—using less energy meant lower costs and a smaller carbon footprint.

| Material | Characteristic | Benefit |

|---|---|---|

| Polymer Cables | Lightweight | Reduces motor strain |

| Flexible | Minimizes wear and tear | |

| Resilient | Withstands harsh environments | |

| Steel Wire Ropes | Heavy | High load-bearing capacity |

| Less Flexible | Can cause more mechanical stress |

Environmental Resilience

Living near the coast, I often worry about corrosion from the salty air. That's why polymer cables are a game-changer—they resist moisture and corrosion beautifully. This makes them perfect for humid or coastal regions6 like mine. The peace of mind knowing that these cables won’t rust or degrade quickly is invaluable, especially in environments where maintenance can be a logistical challenge.

Application in Modern Elevator Design

Another unexpected benefit of polymer cables is the quiet operation they offer. When we installed them in a residential building, the reduction in noise was significant, creating a much more pleasant environment for the residents.

Plus, from an installer’s perspective, these cables are much easier to work with due to their lightweight properties. This not only speeds up installation but also cuts down on costs—a win-win for everyone involved.

While steel wire ropes still have their place for certain high-load applications, I’m convinced that polymer cables are paving the way forward in elevator technology. Their benefits make them an option worth considering for anyone looking to upgrade or design a modern elevator system.

Polymer cables reduce energy consumption in elevators.True

Their lightweight nature decreases motor load, saving energy.

Polymer cables are heavier than steel wire ropes.False

Polymer cables are lighter, reducing strain on elevator motors.

Are there emerging alternatives to steel wire ropes?

Imagine lifting something heavy with ease, like magic, thanks to innovative rope materials.

Alternatives to steel wire ropes are emerging, such as synthetic ropes like HMPE and Kevlar, known for their lighter weight, flexibility, and resistance to corrosion. These are especially useful in industries where weight and maneuverability take precedence over sheer strength.

Synthetic Ropes: A Rising Contender

I remember the first time I encountered synthetic ropes while working on a project at the docks. At first glance, they seemed too light to be of any use compared to the hefty steel ropes I was used to. But then, I discovered that these ropes, particularly those made from high-modulus polyethylene7 (HMPE) and Kevlar, were making waves in industries where every ounce counts. Their impressive strength-to-weight ratios mean that they can do the heavy lifting without weighing you down, which is why they’re increasingly popular in sectors like maritime.

Table: Comparison of Steel vs. Synthetic Ropes

| Property | Steel Wire Rope | Synthetic Rope (HMPE/Kevlar) |

|---|---|---|

| Weight | Heavy | Lightweight |

| Tensile Strength | High | Moderate |

| Flexibility | Limited | Excellent |

| Corrosion Resistance | Requires Coating | Inherent |

| Cost | Varies | Generally Higher |

Applications of Synthetic Ropes

Working in offshore drilling and even sports equipment manufacturing8, I've seen how synthetic ropes shine. They don’t rust or lose their strength even when battered by saltwater or UV rays—qualities that make them an attractive choice when you're navigating harsh environments or need to move gear quickly and efficiently.

Challenges and Considerations

Of course, with every benefit comes a trade-off. Despite their perks, synthetic ropes can cost more upfront and might not hold up as well in terms of UV exposure. It's a balancing act between short-term gains and long-term needs. I’ve learned firsthand that when you require maximum tensile strength, nothing beats the reliability of good old steel wire ropes.

If you're curious about where synthetic ropes might fit into your operations, digging into industry case studies9 can offer some real-world insights into their performance across various scenarios. This could be the key to figuring out whether they could be the right fit for your next big project.

Synthetic ropes are heavier than steel wire ropes.False

Synthetic ropes, like HMPE, are lightweight compared to steel ropes.

HMPE ropes offer better corrosion resistance than steel ropes.True

HMPE ropes are inherently resistant to corrosion, unlike steel ropes.

Conclusion

Steel wire ropes excel in elevator systems due to their unmatched strength and durability, while fiber optic and polymer cables enhance communication and flexibility, respectively.

-

Learn how steel wire ropes maintain durability through advanced corrosion-resistant techniques. ↩

-

Understand how steel wire ropes manage dynamic loads, ensuring smooth elevator operations. ↩

-

Explore the safety standards that steel wire ropes adhere to in elevator systems. ↩

-

This link offers insights into how fiber optics enhance real-time monitoring in elevators, improving safety and efficiency. ↩

-

This resource explains the advantages of using fiber optics for communication in elevators, ensuring reliable connectivity. ↩

-

Learn about the resilience of polymer cables against environmental challenges. ↩

-

Discover the properties of HMPE ropes and how they compare to traditional steel wire ropes. ↩

-

Learn how synthetic ropes enhance performance and safety in sports equipment. ↩

-

Explore real-world examples of synthetic rope applications across different industries. ↩