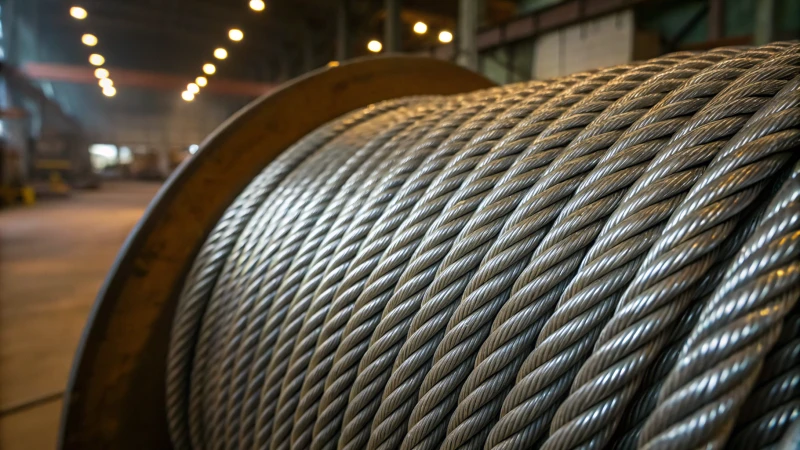

Ever wondered what makes steel wire ropes so reliable in industrial settings? Let's dive in!

The weight capacity of steel wire rope depends on factors like the type of steel, rope construction, diameter, and condition. Environmental influences, such as temperature and moisture, are also crucial. Grasping these factors helps ensure safety and efficiency in industrial applications.

It was a rainy afternoon when I first realized the importance of understanding every little detail about steel wire ropes. I had just started a new project, and selecting the right rope seemed overwhelming with so many factors at play. I learned that things like the type of steel used—whether high-tensile or stainless—and the rope's construction were critical. The diameter also mattered more than I initially thought.

But it wasn't just about the materials; the condition of the rope was crucial too. I remember inspecting ropes for wear and corrosion, understanding that neglecting these could drastically reduce their load-bearing capacity by up to 30%. Then there were the environmental conditions. I had to consider how extreme temperatures and moisture could impact the rope's performance.

Through this experience, I realized that choosing the right steel wire rope isn't just a technical decision—it's about ensuring the safety and success of a project. It's fascinating how these ropes, with corrosion-resistant coatings and high-performance alloys, can improve their lifespan and load capacity by up to 40%. It's all about knowing what you're working with and why it matters.

Steel type affects wire rope weight capacity.True

The type of steel used impacts the strength and durability of the rope.

Diameter does not influence wire rope strength.False

Larger diameters generally increase the weight capacity of wire ropes.

How Does Steel Type Affect Wire Rope Strength?

Have you ever wondered how the type of steel affects the strength of wire ropes? I have, especially when safety and efficiency are on the line.

The type of steel used in wire ropes significantly impacts their strength by affecting tensile strength, flexibility, and resistance to corrosion. High-tensile steel increases load capacity, while stainless steel excels in environments prone to corrosion.

The Role of Steel Composition

I've often found myself contemplating the distinct advantages that different steel types offer when it comes to wire ropes. It reminds me of the time I was choosing between a sturdy high-tensile steel rope for a demanding project and a stainless steel one for a moisture-prone area. Each type seemed perfect for its own scenario. High-tensile steel, with its exceptional strength1, is a top choice when you need maximum load-bearing capacity. Meanwhile, stainless steel is my go-to for environments where corrosion is a constant threat, like those exposed to moisture or chemicals.

Understanding Tensile Strength

Tensile strength is such a crucial factor, isn't it? It determines just how much weight a wire rope can handle. I recall comparing the tensile strengths of various ropes when faced with a challenging lifting task:

| Steel Type | Tensile Strength (MPa) |

|---|---|

| High-Tensile | 1770 - 2160 |

| Stainless | 690 - 1000 |

| Galvanized | 1370 - 1570 |

High-tensile ropes generally have the edge here, offering greater tensile strength and thus enabling us to push weight limits further.

Flexibility and Durability

I've noticed that flexibility often affects how well a rope performs in dynamic settings. For instance, high-tensile steel ropes might be less flexible, which can impact their ability to bend without breaking. I remember this one project where stainless steel's flexibility and durability2 truly shone through in harsh conditions.

Impact of Environmental Conditions

Environment plays a pivotal role in rope selection. There was this time when I needed a rope for marine use; naturally, stainless steel was my choice due to its superior anti-corrosive properties. However, with high-tensile steel, I had to consider additional coatings to prevent degradation. If you're curious about how environmental factors influence rope performance, check out this guide3.

Applications Across Industries

Different industries call for specific attributes based on their requirements. Take construction sites, for instance—they often choose high-tensile ropes for heavy lifting tasks. In mining, stainless steel is preferred to combat underground moisture exposure.

In summary, understanding how steel type affects wire rope strength is invaluable for making informed decisions that enhance safety and efficiency across diverse applications.

High-tensile steel wire ropes have the highest tensile strength.True

High-tensile steel ranges from 1770 to 2160 MPa, higher than other types.

Stainless steel wire ropes are more flexible than high-tensile ones.True

Stainless steel offers greater flexibility and durability in harsh conditions.

How Does Rope Construction Influence Load Capacity?

Have you ever wondered why some ropes hold up mountains while others snap under pressure?

Rope construction plays a crucial role in load capacity by shaping how stress is distributed across strands and wires. Factors like the strand pattern, core type, and material quality directly affect a rope's strength and durability.

Understanding Rope Construction

When I first delved into the world of wire ropes, I was amazed by how much the construction influenced their strength. Different strand patterns4 like 6x19 and 6x36 are not just numbers—they represent different flexibilities and strengths. I once had to choose a rope for a project that required both flexibility and robustness, and understanding these patterns made all the difference.

| Strand Pattern | Characteristics | Application |

|---|---|---|

| 6x19 | More wires, flexibility | General lifting |

| 6x36 | Fewer wires, higher load | Heavy machinery |

The Importance of Core Type

I vividly remember a situation where the core type of a wire rope was the deciding factor. Whether it’s fiber or steel, the core significantly influences performance. A steel core enhances strength, but if you need flexibility, a fiber core might be your best bet. In a previous project, switching to a fiber core saved us from a lot of hassle under stress.

Material Quality and Load Capacity

Choosing between high-tensile steel and stainless steel can feel like choosing between apples and oranges, but it's essential. High-tensile steel offers unmatched load-bearing capacity but demands diligent maintenance. On the other hand, stainless steel's resistance to corrosion is perfect for marine environments5. I’ve learned that pairing the right material with the right application is key.

| Material | Advantages | Best Used In |

|---|---|---|

| High-Tensile | Superior load capacity | Construction, Mining |

| Stainless Steel | Corrosion resistance | Marine, Offshore |

Environmental Considerations

Environmental factors can be sneaky; they creep up on you when you least expect it. Moisture, temperature swings, and chemicals can gradually weaken your rope. I recall a project near the coast where we used corrosion-resistant coatings, and it extended the rope’s lifespan significantly—by about 40%! It’s incredible how these little decisions make such a big impact.

In essence, each aspect of rope construction—from strand patterns to material selection—interacts in ways that can make or break your project. Industries must weigh these factors carefully to ensure safety and efficiency, especially when heavy loads are involved.

By grasping these intricacies of rope construction, industries can make informed choices that align with operational needs and safety standards. Proper selection is not just about ticking boxes; it's about ensuring the longevity and reliability of essential equipment for heavy-duty tasks.

6x19 ropes have more wires than 6x36.True

The 6x19 strand pattern has more wires, offering greater flexibility.

Fiber core ropes are stronger than steel core ropes.False

Steel cores enhance strength, while fiber cores improve flexibility.

Why Does Environmental Exposure Matter for Wire Rope Durability?

Ever wondered why some wire ropes last longer than others? The secret often lies in how they handle the elements.

Environmental exposure can drastically reduce wire rope durability by accelerating wear and corrosion, impacting load-bearing capacity by up to 30%. To combat this, using protective coatings and high-performance alloys can increase lifespan by 40%, ensuring safety and longevity in challenging conditions.

How Temperature Affects Wire Ropes

I've always found it fascinating how temperature can play such a pivotal role in wire rope6 performance. Imagine you're in the desert, the sun blazing, and your wire ropes are expanding like they're trying to escape the heat. Then picture a cold, winter morning where these same ropes feel like they're made of glass, brittle and unforgiving. Temperature changes make steel fibers expand and contract, which stresses the ropes and can lead to damage over time.

| Temperature Effect | Impact on Wire Ropes |

|---|---|

| High Temperatures | Weakens steel, reduces strength |

| Low Temperatures | Increases brittleness |

The Role of Moisture in Corrosion

I've seen firsthand how moisture can wreak havoc on wire ropes, especially in places with high humidity or near the sea. It's like rust's best friend, speeding up corrosion and compromising the structural integrity7 of the rope. This significantly reduces its ability to bear loads.

- Galvanized vs. Stainless Steel:

- Galvanized steel offers a decent shield against rust but isn't invincible.

- Stainless steel is like your best buddy in a wet environment, offering great resistance to corrosion.

Chemical Exposure and Material Degradation

Back when I worked on projects involving harsh chemicals, I quickly learned that not all wire ropes are up to the task. Some chemicals can degrade wire ropes faster than you'd think. Picking the right material for the environment is key to avoiding premature failure8.

- Protective Coatings:

- PVC or nylon coatings are like raincoats for ropes against chemicals, though they have their limits.

- Specialized coatings can add extra layers of protection when things get tough.

Strategies for Mitigation

It's crucial to choose the right materials designed for specific environmental conditions to tackle these challenges head-on. By using high-performance alloys and advanced protective coatings, you can extend a wire rope's lifespan significantly. Regular inspections and maintenance practices are essential to ensure they remain safe and functional.

For further insights, explore effective maintenance strategies9 to enhance durability and performance in demanding environments.

High temperatures weaken steel fibers in wire ropes.True

Extreme heat reduces the strength of steel, compromising rope durability.

Moisture exposure has no effect on wire rope corrosion.False

Moisture accelerates corrosion, reducing the rope's structural integrity.

How do wear and corrosion affect wire rope performance?

Ever wonder why your wire ropes don't last as long as they should? Let's delve into the unseen foes that wear them down.

Wear and corrosion significantly weaken wire ropes by eroding their strength and flexibility. By conducting regular inspections, applying proper maintenance, and choosing corrosion-resistant materials, you can extend their lifespan and maintain safety in various applications.

Factors Contributing to Wear and Corrosion

Every time I walk into a construction site, I'm reminded of just how unforgiving the environment can be on our trusty wire ropes. Over the years, I've seen ropes come out of abrasive conditions looking more like frayed shoelaces than industrial-grade equipment. Elements like abrasive environments10 or relentless humidity don't help—they fast-track the degradation process. By understanding these factors, I can make better choices about which ropes to use and how to care for them.

| Factor | Impact |

|---|---|

| Abrasion | Physical wearing of the wire surface |

| Moisture | Promotes corrosion and weakens material |

| Chemicals | Cause chemical reactions weakening the rope |

Effects on Performance

I remember the first time a wire rope snapped during a project. It was a wake-up call about how vital performance is, especially when it comes to load capacity, flexibility, and safety. Wear thins out the material, while corrosion eats away at the metal itself. Both of these issues cut down on the rope's strength and can even lead to catastrophic failure.

- Load Capacity Reduction: I've learned that wear can eat away at the wires' diameter, making them less capable of bearing loads. Corrosion makes this worse by weakening the core metal.

- Flexibility Loss: As wear progresses, the ropes lose their maneuverability—it's like trying to bend a steel rod.

- Safety Risks: A compromised rope is like a ticking time bomb. Regular inspections and opting for corrosion-resistant materials11 are non-negotiable.

Maintenance and Prevention Strategies

Prevention is a mantra I live by—it's cheaper than dealing with disasters later. Regular maintenance isn't just a task; it's a lifeline for these ropes. This includes thorough visual inspections, applying lubrication, and swapping out worn sections. Using high-performance alloys or coatings can add years to the rope's life.

- Inspection Protocols: I make it a point to keep an eye out for signs of wear or corrosion.

- Lubrication: This reduces friction and acts like a shield against moisture.

- Material Selection: Investing in materials like stainless steel or galvanized wires pays off when you're battling environmental elements.

By integrating these strategies, I ensure that our wire ropes not only last longer but also perform reliably, enhancing both operational efficiency and safety in our work.

Abrasive environments increase wire rope wear.True

Abrasive environments cause physical wearing of the wire surface.

Corrosion does not affect wire rope flexibility.False

Corrosion weakens metal, reducing flexibility and increasing fatigue.

Conclusion

The weight capacity of steel wire rope is influenced by factors such as steel type, construction, diameter, condition, and environmental conditions like temperature and moisture.

-

Explore high-tensile steel's applications to understand why it is ideal for heavy-duty uses. ↩

-

Learn about how stainless steel's flexibility can enhance its performance in various environments. ↩

-

Discover how different environments affect the longevity and performance of wire ropes. ↩

-

Discover how different strand patterns affect flexibility and durability. ↩

-

Explore why stainless steel ropes are ideal for marine environments. ↩

-

Discover detailed information about temperature impacts on wire rope strength and durability in various industrial settings. ↩

-

Learn about how moisture accelerates corrosion in wire ropes, affecting their structural integrity. ↩

-

Understand the types of chemicals that can degrade wire ropes and how to mitigate these effects. ↩

-

Explore maintenance strategies that improve wire rope durability in challenging conditions. ↩

-

Discover how different abrasive environments contribute to the wear of wire ropes and learn about protective strategies. ↩

-

Explore materials that offer enhanced resistance to corrosion, increasing the durability of wire ropes. ↩