Ever wondered what keeps elevators smoothly zipping up and down?

Safety standards for elevator steel wire ropes, like ISO 4344 and EN 12385-5, lay down crucial guidelines for construction, tensile strength, and fatigue resistance. They ensure these ropes can safely handle loads with a minimum safety factor of 5:1, guaranteeing reliability in every ride.

When I first delved into elevator safety, I realized it’s not just about regulations but ensuring peace of mind. Imagine stepping into an elevator knowing every steel rope has been meticulously tested and inspected. Let’s explore the inspections and expert insights that keep these cables—and us—safe.

ISO 4344 sets standards for elevator steel wire ropes.True

ISO 4344 specifies requirements for construction and performance.

Elevator ropes have a safety factor of 3:1.False

The minimum safety factor for elevator ropes is actually 5:1.

How Do International Standards Like ISO 4344 Define Elevator Rope Safety?

Ever wondered what keeps elevator rides smooth and secure? Dive into how ISO 4344 sets the gold standard for elevator rope safety, ensuring every ride is as safe as it is efficient.

ISO 4344 establishes detailed guidelines for elevator rope safety, focusing on construction standards, minimum breaking strength, and rigorous safety evaluations. These standards are essential to ensure ropes can handle operational demands while maintaining high safety levels.

Understanding ISO 4344's Role in Elevator Safety

I remember the first time I learned about the intricacies of elevator safety standards. It was during a project where we were tasked with upgrading an old building's elevator system. It became clear that standards like ISO 4344 are not just technical guidelines; they're essential for ensuring our everyday vertical journeys are safe and sound.

ISO 4344 plays a pivotal role in standardizing elevator rope safety globally. This international standard1 lays down the specifications for steel wire ropes used in elevators, ensuring they can safely handle expected loads. It’s like the backbone of elevator reliability.

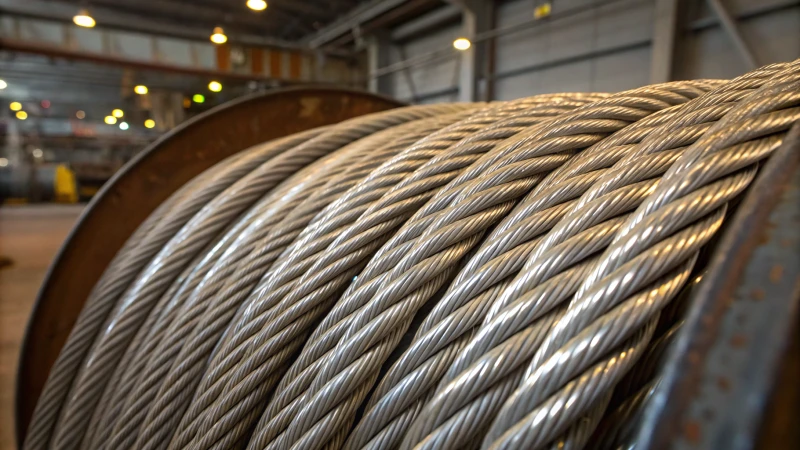

Rope Construction and Materials

Back when I first started working on construction projects, I quickly realized the importance of material quality in ensuring safety. The standard emphasizes using high-quality materials, such as galvanized or stainless steel, in rope construction to resist corrosion and wear. These ropes must meet specific tensile strength2 requirements, ensuring they are robust and durable.

| Material | Benefits |

|---|---|

| Galvanized Steel | Corrosion resistance |

| Stainless Steel | High strength and durability |

Minimum Breaking Strength

One of the most crucial aspects of ISO 4344 is the minimum breaking strength requirement. I’ve seen firsthand how this requirement plays out in real-world scenarios. Ropes need a safety factor of at least 5:1, meaning they should withstand five times the maximum load they are expected to carry. This ensures reliability even under high stress.

Safety Checks and Testing

Routine safety checks have always been a priority in my projects, just as ISO 4344 mandates. These include visual inspections and tensile tests3, which help spot wear and tear early and ensure ropes maintain their strength under pressure.

Fatigue Resistance Testing

Fatigue resistance testing is something I appreciate for its ability to preemptively identify issues before they become critical. Ropes undergo these tests to evaluate their performance under repeated stress cycles, which is vital for ensuring longevity4 and operational efficiency.

Regular compliance with these standards is not just a legal requirement but a moral one, ensuring the safety of everyone who uses elevators daily. By adhering to ISO 4344, manufacturers and operators like us can guarantee that elevators remain safe for public use, preventing accidents due to rope failure.

ISO 4344 mandates a safety factor of 5:1 for elevator ropes.True

ISO 4344 requires ropes to withstand five times the maximum load for safety.

Stainless steel ropes are weaker than galvanized steel ropes.False

Stainless steel ropes offer high strength and durability, not weaker.

What are the key inspection practices for elevator steel wire ropes?

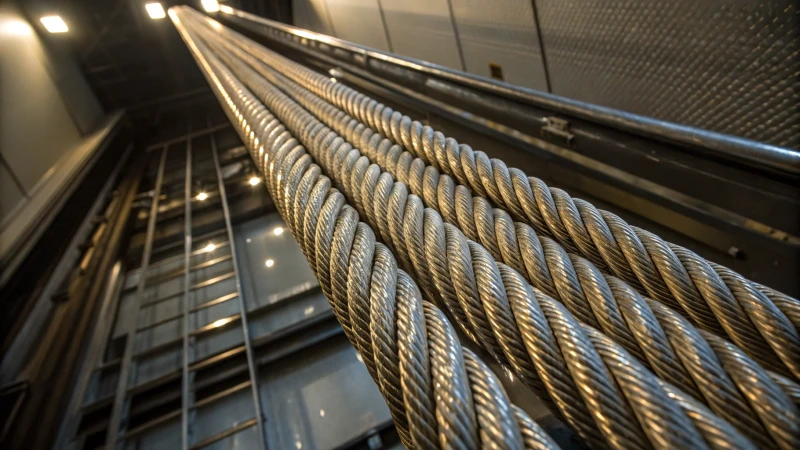

Remember the last time you trusted an elevator to whisk you up a dozen floors? That ride depends on something as humble as steel wire ropes. Let’s delve into the essential inspection practices that keep these elevator ropes in top shape.

The key inspection practices for elevator steel wire ropes include visual inspections, diameter measurements, lubrication checks, and non-destructive testing. These steps are crucial for ensuring safety, compliance, and extending the life of the ropes.

Visual Inspections

Visual inspections are our first line of defense against potential failures in elevator steel wire ropes. Let me share a quick story about the time I first learned the importance of a good visual inspection. I was shadowing a seasoned elevator inspector who pointed out some subtle signs of wear on a steel rope that I would've missed—tiny wire breaks that looked like nothing but could've spelled trouble later on. Regularly checking for broken wires, corrosion, and distortion helps us catch problems early and prevent costly repairs or accidents.

Diameter Measurements

Measuring the diameter of steel wire ropes is essential to assess their wear and tear. I still remember my first attempt at measuring the diameter of a steel wire rope. Armed with a caliper, I felt like a detective on a mission. A decrease in diameter can mean internal corrosion or excessive wear, and catching these early is crucial. Measuring at various points ensures the rope meets industry standards5. Consistent monitoring helps maintain optimal safety and performance levels.

| Inspection Metric | Ideal Condition |

|---|---|

| Diameter | Within tolerance |

| Surface Condition | No rust or breakage |

Lubrication Checks

Proper lubrication is vital for maintaining the functionality and longevity of steel wire ropes. I once worked with an elevator that had been neglected in the lubrication department, and let me tell you, the friction noise was unbearable! Inspectors should check for adequate lubrication levels and apply more if necessary because environmental factors can degrade lubrication over time, leading to increased wear. Regular lubrication checks help ensure smooth operation.

Non-Destructive Testing (NDT)

Non-destructive testing methods are like having X-ray vision for steel wire ropes. Techniques such as magnetic flux leakage or ultrasonic testing offer deeper insight into the condition without causing damage. These techniques can detect flaws not visible to the naked eye, such as internal fractures or corrosion. Implementing NDT6 in routine inspections enhances accuracy and reliability.

Compliance with Safety Standards

Adhering to safety standards such as ISO 4344 and EN 12385-5 isn’t just about ticking boxes; it’s about ensuring every ride is safe. These guidelines specify construction, tensile strength, and fatigue resistance requirements for elevator steel wire ropes. Ensuring compliance improves safety and extends service life. I believe regular training for inspection personnel on these standards is crucial because it keeps us informed about industry developments.

Visual inspections can prevent elevator accidents.True

Early detection of wear and corrosion reduces failure risk, enhancing safety.

Non-destructive testing damages steel wire ropes.False

NDT methods assess rope condition without causing any physical damage.

How Does Tensile Strength Affect Elevator Rope Performance?

Ever wonder why elevator rides feel so safe and smooth? It all comes down to the hidden strength of those sturdy ropes holding everything together.

Tensile strength is crucial for elevator ropes, as it dictates how much weight they can safely bear before failing. Ropes with higher tensile strength offer improved performance and safety, especially in high-demand environments like tall buildings.

Understanding Tensile Strength in Elevator Ropes

I've often marveled at how effortlessly elevators whisk us up to dizzying heights. But behind the scenes, it's all about the tensile strength of the ropes doing the heavy lifting—quite literally! Tensile strength measures how much force a rope can take while being pulled tight, and it's typically represented in megapascals (MPa) or pounds per square inch (psi). Imagine this: if you're holding onto a rope made of high-carbon steel, you're dealing with a material known for its toughness and resilience.

In the realm of elevator systems, picking ropes with sufficient tensile strength is a no-brainer. It ensures that the ropes can handle not just the weight of the elevator cabin but also the passengers and any extra loads. There's a guideline, ISO 43447, that emphasizes a minimum breaking strength with a safety factor of at least 5:1. Essentially, this means the ropes should be able to carry five times the maximum load they might encounter.

Impact on Performance

When I think about elevator ropes, it's clear that tensile strength plays a massive role in how well they perform. Ropes boasting high tensile strength are like the superheroes of the elevator world—they're more resistant to fatigue and wear and tear, which means they last longer and require less upkeep. This is super important in places like skyscrapers8, where elevators are zipping up and down all day long.

On the flip side, ropes with less tensile strength can be more problematic. They need frequent checks and replacements, which leads to downtime and higher costs. Plus, they're more at risk of snapping under stress, which is definitely not something you want happening.

Evaluating Rope Specifications

So when it comes to choosing elevator ropes, it's crucial to look at specs like diameter, construction type (like 6x19 or 8x19), and core type (fiber or steel). Here's a quick rundown:

| Specification | Description |

|---|---|

| Diameter | Larger diameters generally offer higher tensile strength |

| Construction | Determines flexibility; affects tensile properties |

| Core Type | Steel cores offer better strength than fiber cores |

Having a solid grasp of these factors along with tensile strength means people like John9 or Emma10 can make smart choices tailored to their elevator needs. It's always wise to chat with suppliers who provide solid technical support and advice on picking the best product for your situation.

Elevator ropes with high tensile strength last longer.True

High tensile strength improves resistance to fatigue and wear, extending lifespan.

Fiber core ropes have higher tensile strength than steel cores.False

Steel cores offer better tensile strength compared to fiber cores.

Why Does Fatigue Resistance Matter for Elevator Wire Ropes?

Imagine the hum of an elevator as it carries you safely between floors, all thanks to the unsung hero: the wire rope's fatigue resistance.

Fatigue resistance in elevator wire ropes is essential because it ensures safety and longevity by allowing ropes to endure the repetitive stress of elevator cycles without failing. This minimizes the risk of dangerous malfunctions.

Understanding Fatigue Resistance in Wire Ropes

When I think about the relentless journey an elevator takes each day—up, down, repeat—I can't help but admire the wire ropes that make it possible. Fatigue resistance is the hero here, letting these ropes endure countless bending cycles without snapping. Every time an elevator ascends or descends, those ropes face intense cyclic loading. The secret to enhancing their fatigue resistance? It's all in the construction. By using many smaller wires instead of a few thick ones, we make the ropes more flexible and capable of handling more bends. It reminds me of the way my old hiking boots, worn and supple, could take on any trail.

The Impact of Material Quality on Fatigue Resistance

Just like choosing a sturdy pair of boots for a hike, selecting the right materials for wire ropes is crucial. High-quality steel alloys are often preferred because they resist both fatigue and wear. And just like a waterproof coating on my favorite raincoat, zinc galvanization on these ropes helps fight off corrosion, another enemy in the battle against fatigue.

| Material Type | Benefits |

|---|---|

| High-quality steel alloys | Enhanced fatigue resistance |

| Zinc galvanized | Corrosion protection |

Safety Implications of Fatigue Resistance

Imagine riding an elevator and suddenly wondering about those ropes overhead. That thought alone underscores why fatigue resistance is non-negotiable. Failing to meet standards like ISO 4344 could lead to catastrophic failures. Regular safety checks11, including visual inspections and fatigue tests, are our assurance against such risks. It's like keeping my car in check with routine maintenance—it not only prevents accidents but prolongs the life of the vehicle.

Advancements in Wire Rope Technology

In recent times, I've been fascinated by how technology keeps pushing boundaries. Some manufacturers now blend synthetic materials with steel to create hybrid ropes that boast even greater flexibility and resilience. These innovations remind me of how modern tech has revolutionized my daily life—it's thrilling to see similar strides in industrial applications.

These technological innovations12 are not just cool; they're paving the way for safer and more efficient elevators worldwide.

Elevator wire ropes with smaller wires have better fatigue resistance.True

Smaller wires increase flexibility, enhancing fatigue resistance in wire ropes.

Zinc galvanization reduces the fatigue resistance of wire ropes.False

Zinc galvanization protects against corrosion, indirectly supporting fatigue resistance.

Conclusion

Elevator steel wire ropes must meet safety standards like ISO 4344, ensuring construction quality, tensile strength, and fatigue resistance for reliable performance and safety in vertical transportation.

-

Explore how ISO 4344 sets global benchmarks for elevator rope construction and safety. ↩

-

Learn about tensile strength specifications crucial for elevator rope durability. ↩

-

Understand different methods of tensile testing to ensure rope strength. ↩

-

Discover why fatigue resistance is essential for the longevity of elevator ropes. ↩

-

Understanding diameter tolerances helps ensure that ropes meet safety and performance requirements. ↩

-

Implementing NDT provides deeper insights into the rope's condition without causing damage. ↩

-

Clicking this link offers in-depth insights into international standards ensuring elevator rope safety and performance. ↩

-

Explore how elevator ropes function in skyscrapers, highlighting stress factors and safety measures. ↩

-

Learn about the responsibilities and challenges faced by construction procurement managers like John. ↩

-

Discover key aspects of a mining procurement officer's duties, reflecting Emma's professional landscape. ↩

-

Explore this link to understand the significance of conducting routine inspections and tests on elevator wire ropes to maintain safety and prolong their lifespan. ↩

-

This link offers insights into new technologies that enhance the durability and performance of elevator wire ropes, providing cutting-edge solutions for safety challenges. ↩