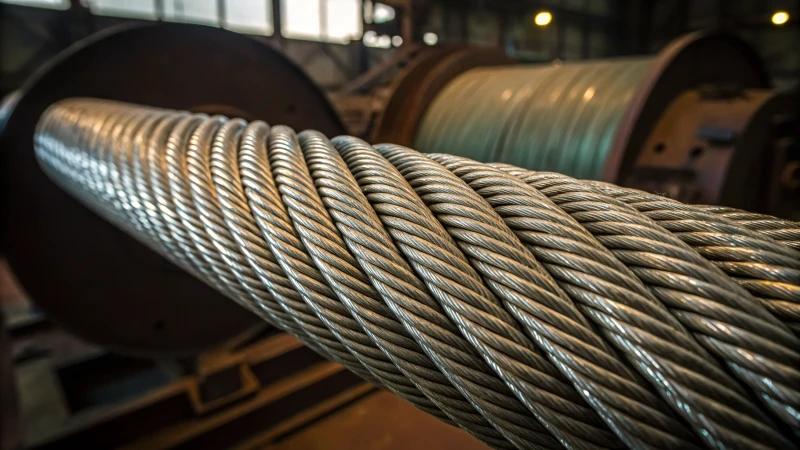

Ever wondered how to pick the perfect steel wire rope for your automotive needs?

To choose the most durable steel wire rope for automotive manufacturing, focus on materials with high tensile strength and corrosion resistance like alloy and stainless steel. Evaluate environmental conditions, load capacity, and safety standards to ensure long-lasting performance.

Picture this: I was once tasked with selecting the right steel wire rope for a major automotive project. The pressure was on, as the safety and efficiency of the entire operation hinged on my decision. That’s when I learned that understanding the material properties and industry standards isn't just important—it’s essential. Alloy and stainless steel became my go-to options because of their unmatched strength and resistance to rust, ensuring the ropes could handle anything thrown their way. Delving into the specifics, such as tensile strength and compliance with safety regulations, helped me make an informed choice. This experience taught me that a careful analysis of environmental factors and load capacity is key in making a decision you can trust.

Alloy steel ropes have higher tensile strength than stainless steel.True

Alloy steel is engineered for high tensile strength, ideal for heavy loads.

Environmental conditions don't affect the choice of steel wire rope.False

Environmental factors like humidity and temperature can impact durability.

Why Are Material Properties Crucial in Selection?

Ever wondered why some materials make the cut while others don't? It's all about understanding their properties and how they hold up in the real world.

When I choose materials, I always weigh tensile strength, ductility, hardness, and toughness. These properties reveal how a material reacts under stress and impact, guiding its use in various scenarios.

Understanding Mechanical Properties

Mechanical properties are like a material's personal diary, telling the story of how it behaves under pressure. I've seen firsthand how tensile strength can be a game-changer. Imagine working with stainless steel1—its ability to withstand immense loads without breaking is why I always trust it for robust applications.

Ductility is another fascinating property. Think about copper; it's like the yoga master of materials—flexible yet unbreakable, perfect for projects where bending and shaping are essential. Meanwhile, hardness helps me decide how well a material can resist wear and tear—diamond is the gold standard here.

Finally, toughness is like the marriage between strength and flexibility. It’s crucial for materials that need to absorb shock without cracking, much like rubber, which I've relied on countless times in demanding situations.

| Property | Definition | Example Material |

|---|---|---|

| Tensile Strength | Max load before breaking | Stainless Steel |

| Ductility | Ability to deform without fracture | Copper |

| Hardness | Resistance to permanent shape change | Diamond |

| Toughness | Absorbs energy before fracturing | Rubber |

Evaluating Thermal and Electrical Properties

Thermal and electrical properties are just as important, especially when dealing with heat or power. Thermal conductivity, for instance, plays a big role in projects where heat dissipation is critical. Aluminum has been my go-to material here, particularly because it efficiently channels heat away.

Then there's electrical conductivity, crucial for anything electronic. Silver’s superior performance in conducting electricity makes it indispensable in these applications.

Exploring Chemical Properties

Chemical properties have saved me from many potential disasters by indicating how materials will react with their surroundings. Corrosion resistance is a must-have for longevity in challenging environments, which is why galvanized steel2 never fails to make my shortlist.

I’ve also learned the hard way that chemical stability can make or break a material's suitability when exposed to reactive substances.

The Role of Environmental Factors

Environmental resilience can’t be overlooked. UV resistance is crucial for outdoor applications—I’ve found it essential for long-term durability. Water resistance ensures that materials can withstand moisture-rich environments, which is vital for industries like construction or marine applications.

When selecting materials, these factors—strength, flexibility, durability, and environmental resistance—are my guiding stars. They help ensure I make informed decisions that lead to successful projects every time.

Stainless steel has low tensile strength.False

Stainless steel is known for its high tensile strength, not low.

Copper is highly ductile, suitable for shape changes.True

Copper's high ductility makes it ideal for applications requiring deformation.

How Does Corrosion Resistance Impact Longevity?

Have you ever wondered why some materials stand the test of time while others crumble under pressure?

Corrosion resistance significantly influences longevity by safeguarding materials from degradation. For example, stainless steel resists corrosion effectively, which extends its lifespan and minimizes maintenance costs. Choosing the right materials can lead to enhanced durability, especially in challenging environments.

Understanding Corrosion Resistance

Imagine watching a shiny new car slowly rust away in the rain. That's corrosion at work. It's this sneaky process where metals degrade due to chemical reactions with the environment, like moisture or oxygen. Some materials, like stainless steel, have high corrosion resistance and can brave these elements, standing strong and functional over time.

Key Factors Influencing Corrosion Resistance

-

Material Composition: I remember the first time I learned about alloys like stainless steel containing chromium. This magical element creates a protective barrier, like a superhero cape for metal, shielding it from further damage.

-

Environmental Conditions: Ever been to the beach and noticed how quickly things rust near the ocean? Saltwater accelerates corrosion, so materials in such environments need to be extra tough.

-

Coatings and Treatments: Think of galvanization as a spa treatment for metals, enhancing their resistance with protective layers. Essential in environments where corrosion is unavoidable.

Longevity Implications of Corrosion Resistance

When I think about how materials resist corrosion, it reminds me of choosing a long-lasting friendship over a fleeting one. Products made from corrosion-resistant materials last longer, saving on repairs and replacements. This is crucial in industries like construction and mining where conditions are rough.

Case Study: Steel Wire Ropes

- Material Choice: Alloy or stainless steel is often used in steel wire ropes because of their strength and resistance to harsh environments.

- Performance: These ropes endure stress and wear, meaning fewer replacements are needed.

- Industry Demand: Market trends show a 6% annual growth in demand for high-performance steel wire ropes, driven by automotive and construction sectors needing durable components.

| Material Type | Corrosion Resistance | Typical Use Case |

|---|---|---|

| Stainless Steel | High | Construction, Marine |

| Galvanized Steel | Moderate | Industrial, Infrastructure |

| Aluminum Alloys | Variable | Aerospace, Automotive |

Benefits of Investing in Corrosion Resistance

Investing in high corrosion resistance is like putting money in a sturdy savings account—it's about long-term gains and safety. For instance, using stainless steel wire ropes in construction not only ensures safety but also meets regulations.

Understanding how corrosion resistance impacts longevity is vital for decision-makers in procurement and manufacturing. It ensures optimal performance from construction3 projects to marine4 operations.

Future Considerations

As material science advances, I can't help but feel excited about the potential for even better corrosion resistance. Innovations will lead to more sustainable and durable solutions, keeping us ahead in industries like mining5 and heavy machinery6. Staying informed about these changes can maintain a competitive edge and ensure safe, efficient operations.

Stainless steel is highly corrosion resistant.True

Stainless steel contains chromium, forming a protective oxide layer.

Galvanized steel has higher corrosion resistance than stainless steel.False

Galvanized steel has moderate resistance; stainless steel is higher.

Why is Tensile Strength Crucial for Automotive Applications?

Ever wondered why car materials don't just crumble under pressure?

Tensile strength is crucial in automotive applications because it ensures materials can handle stress, enhancing both safety and performance by preventing deformation and breakage under load.

Understanding Tensile Strength in Vehicles

I remember the first time I got behind the wheel; the thrill was undeniable. But it wasn't just the speed or the freedom that amazed me—it was the solid feel of the vehicle. That's thanks to tensile strength. It's the maximum stress a material can endure while being stretched or pulled before breaking. This property is absolutely vital for car parts that face dynamic loads and high-pressure conditions.

Think about the steel in the chassis construction7. It must be strong enough to keep you safe if something goes wrong on the road. The high tensile strength ensures that even in a crash, the vehicle's structure holds up to protect you and your passengers. And let's not forget about engine components. They need to withstand both extreme temperatures and mechanical stress.

Material Selection Based on Tensile Properties

Choosing materials for cars is like picking the right ingredients for a perfect recipe. Engineers have to strike a balance between weight, cost, and performance, and tensile strength plays a massive role in that decision. Materials like advanced high-strength steel (AHSS)8 are often chosen because they provide necessary strength without adding too much weight, which is crucial for fuel efficiency and handling.

Here's how some common automotive materials stack up:

| Material | Tensile Strength (MPa) | Applications |

|---|---|---|

| AHSS | 600 - 1500 | Structural components |

| Aluminum alloys | 200 - 600 | Engine parts, body panels |

| Carbon fiber-reinforced | 600 - 900 | Performance vehicles |

The Role of Tensile Strength in Safety and Durability

Safety is something we often take for granted until it's really put to the test. I once had a close call that reminded me of the importance of having a car built with high tensile strength materials. Safety regulations set strict requirements for tensile strength to minimize failure risks. A car's crumple zones, designed to absorb impact energy, depend on materials with specific tensile properties to deform predictably during stress.

And when it comes to emergency components like seatbelts and airbag housings, consistent tensile strength is key to their effective performance, saving lives by maintaining integrity under sudden forces.

Plus, durability matters too. Automakers aim to produce vehicles that last longer without major performance drops. High tensile strength materials ensure that components like suspension systems and drivetrains can withstand constant use without wearing down quickly.

Steel chassis must have high tensile strength for safety.True

High tensile strength in steel chassis protects passengers during collisions.

Aluminum alloys are stronger than carbon fiber-reinforced materials.False

Carbon fiber-reinforced materials generally have higher tensile strength than aluminum alloys.

How Can I Ensure Compliance with Safety Standards?

Navigating the maze of safety compliance can feel like trying to crack a secret code, but it's essential for a safe work environment.

To ensure compliance with safety standards, I focus on regular audits, comprehensive employee training, and setting up clear protocols. Involving stakeholders and embracing technology further strengthens these efforts.

Conducting Regular Safety Audits

I remember my first safety audit—it was nerve-wracking! However, it quickly became apparent how vital these checks are. Regular audits help pinpoint potential hazards and make sure our safety measures are up to scratch. I usually rely on a team of experts or sometimes bring in external specialists to provide an unbiased view. Staying ahead of the latest safety regulations is crucial, and auditing ensures we don't miss a beat.

| Audit Frequency | Key Focus Areas |

|---|---|

| Monthly | Equipment Checks |

| Quarterly | Training Effectiveness |

| Annually | Policy Review & Updates |

Employee Training Programs

Training has been a game-changer for us. I still recall the first time we implemented role-specific workshops; the increase in awareness and confidence was palpable. These sessions are tailored to ensure they resonate with every role in the company, keeping everyone informed about new regulations and protocols. Training programs can be tailored9 to specific roles within the company to ensure relevance and effectiveness.

Establishing Clear Safety Protocols

Setting up clear safety protocols felt like writing a playbook for everyone involved. I made sure these guidelines were accessible and easy to understand, incorporating step-by-step procedures into manuals and digital formats. This helps each team member know exactly what’s expected of them when it comes to maintaining a safe workplace.

Engaging Stakeholders

Getting everyone on board, from employees to management and even external partners, was another pivotal step. I encouraged open communication about safety concerns, which not only empowered my team but also fostered a collaborative spirit. It’s amazing how this approach brings fresh solutions and ownership over safety practices.

Leveraging Technology

Technology has been a huge ally in our compliance efforts. From automating audit schedules to tracking training progress, software solutions have streamlined many processes. I’m always on the lookout for innovative technologies10 that can enhance our efficiency and keep us updated on safety measures in real-time.

Safety compliance is not just a checklist; it's a proactive approach involving constant reviews, active engagement, and smart tools. By focusing on these areas, I've seen firsthand how it cultivates a safer work environment that meets all necessary regulations.

Regular safety audits identify potential hazards.True

Safety audits systematically review conditions to find hazards.

Employee training is optional for safety compliance.False

Training is essential to educate employees on safety standards.

Conclusion

Selecting durable steel wire ropes for automotive manufacturing involves assessing materials like alloy and stainless steel, focusing on tensile strength, corrosion resistance, and environmental factors for optimal performance.

-

Explore this link to understand why stainless steel is ideal for high-load applications due to its excellent tensile strength. ↩

-

Learn about the benefits of galvanized steel in resisting corrosion, enhancing its durability in challenging environments. ↩

-

Discover why stainless steel is preferred for construction due to its strength and resistance to environmental factors. ↩

-

Learn how corrosion-resistant materials benefit marine applications, enhancing durability and reducing maintenance. ↩

-

Explore how mining operations benefit from using corrosion-resistant materials, ensuring equipment longevity. ↩

-

Understand the importance of durable materials in heavy machinery for performance and safety. ↩

-

Learn how tensile strength in car chassis affects vehicle safety and structural integrity. ↩

-

Explore why advanced high-strength steel is favored for lightweight yet strong car designs. ↩

-

Learn how to design effective safety training programs tailored to specific job roles within your organization. ↩

-

Explore how technology solutions can streamline compliance processes and keep safety measures up-to-date. ↩