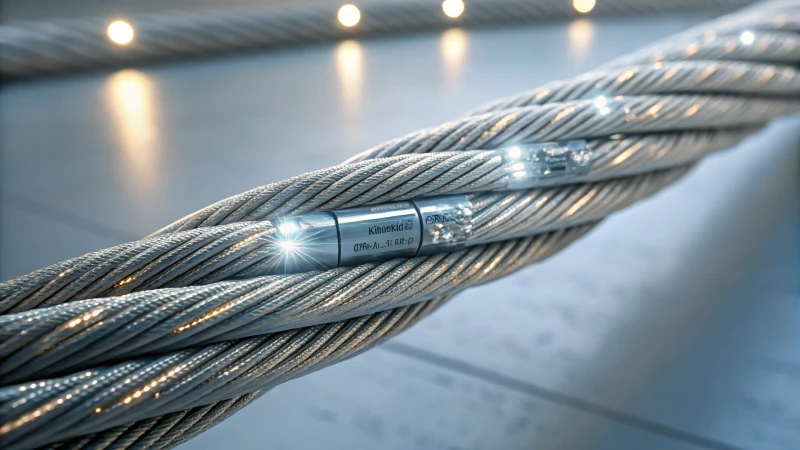

Ever wondered how technology is reshaping the backbone of industries? Enter smart sensors, revolutionizing steel wire rope monitoring with precision and efficiency.

Smart sensors in steel wire ropes offer real-time insights into parameters like tensile stress and corrosion, boosting safety by up to 50% while slashing maintenance costs by 25%. They enable predictive maintenance, prevent unexpected failures, and enhance operational efficiency across various sectors.

I remember the first time I saw a smart sensor in action during a construction project. It was like watching a symphony of data unfold, revealing the hidden stresses and strains our eyes couldn’t see. This technology doesn’t just offer a peek into the health of steel wire ropes—it fundamentally changes how we maintain them. By providing real-time alerts and insights, these sensors empower us to act before a minor issue turns into a major catastrophe. This proactive approach isn't just a leap forward in safety—it's a testament to how we're transforming industries from reactive to predictive, ensuring both efficiency and peace of mind.

Smart sensors reduce maintenance costs by 25%.True

The use of smart sensors in steel wire ropes cuts maintenance expenses.

Smart sensors only monitor tensile stress in steel ropes.False

They also monitor corrosion and other parameters, not just tensile stress.

Why Are Smart Sensors Crucial for Modern Steel Wire Ropes?

Imagine a world where steel wire ropes can talk, telling us when they're worn out or need a check-up. That's the magic of smart sensors!

Smart sensors are game-changers for steel wire ropes, offering real-time insights into tensile stress, corrosion, and fatigue. This technology not only cuts down on unexpected failures and maintenance costs by up to 25% but also boosts safety significantly, making operations smoother and more reliable.

Real-Time Monitoring for Enhanced Safety

Picture yourself on a construction site, the hum of machinery all around, and towering cranes swinging into action. Now imagine if those cranes had a built-in system constantly whispering updates about their health. That's what smart sensors do for steel wire ropes. They're like the vigilant guardians, monitoring every twist and turn. Whether it's the tensile stress that's creeping up or a hint of corrosion setting in, these sensors send alerts straight to control systems. It’s a bit like having a trusty sidekick who warns you before things go wrong.

For example, construction sites1 that rely heavily on cranes find this technology indispensable because it maintains top-notch safety standards.

Predictive Maintenance and Cost Reduction

I've always been fascinated by the idea of fixing problems before they even happen. That's precisely what predictive maintenance with smart sensors allows us to do. Instead of waiting for something to break down, these clever devices give us the heads-up. They say, "Hey, there's a potential issue here," long before it turns into a costly downtime disaster. For industries like mining, where every moment counts and equipment is under constant strain, this isn't just beneficial—it's essential.

In mining operations2, the ability to anticipate issues can save time, money, and a whole lot of headaches.

Data-Driven Insights for Improved Performance

I've always believed in learning from the past to make things better. With smart sensors, we collect mountains of data that tell us stories about wear patterns and performance quirks. By analyzing these insights, we can tweak designs and materials to make steel wire ropes last longer and work harder. It’s like having a crystal ball that not only shows you what’s happening now but also guides you towards improvements.

A detailed analysis3 can reveal ways to enhance the durability and dependability of ropes—a crucial factor for industries like heavy equipment and logistics.

Enhancing Compliance with Safety Standards

Safety is the backbone of any industry using steel wire ropes. With smart sensors, adhering to safety regulations becomes seamless. They keep an eagle eye on rope conditions and provide thorough documentation for inspections and maintenance activities. This is particularly important in areas with stringent safety rules, like Europe4 and North America5.

Here's a quick look at how these sensors help track compliance:

| Inspection Date | Parameter Monitored | Status |

|---|---|---|

| 01/02/2023 | Tensile Stress | Normal |

| 15/03/2023 | Corrosion Levels | Alert |

| 10/04/2023 | Fatigue Signs | Normal |

Integrating smart sensors into steel wire ropes isn't just about adopting new technology; it's about stepping into a future where operations are smarter, safer, and more cost-effective across diverse industries.

Smart sensors reduce maintenance costs by 25%.True

Smart sensors enable predictive maintenance, cutting unexpected downtime and costs.

Smart sensors in steel ropes are only used in Europe.False

Smart sensors are used globally, including North America, for safety compliance.

How Do Smart Sensors Contribute to Predictive Maintenance?

Ever wondered how smart sensors keep your machines running smoothly without a hitch?

Smart sensors play a pivotal role in predictive maintenance by continuously tracking equipment conditions and identifying anomalies early on. This allows for timely, data-driven interventions, drastically cutting down unexpected failures and maintenance expenses.

Understanding the Basics of Smart Sensors

Imagine this: You're sitting at your desk, sipping coffee, when a notification pings on your computer. Your equipment's temperature has spiked, signaling potential trouble. This isn't magic—it's the work of smart sensors. These clever devices marry sensing capabilities with embedded processing, keeping tabs on parameters like temperature, vibration, or pressure. They transform physical data into digital signals, perfect for detailed analysis and avoiding potential disasters.

The Role of Smart Sensors in Data Collection

In my early days managing equipment, I learned the hard way that data is king. Without it, you're just guessing. Smart sensors are like having a team of diligent assistants constantly gathering data, spotting patterns and trends that hint at looming failures. Picture this: a motor’s temperature quietly rising in the background—a smart sensor catches it before it spirals into a costly shutdown.

| Parameter Monitored | Example Sensor Used |

|---|---|

| Vibration | Accelerometer |

| Temperature | Thermocouple |

| Pressure | Pressure Transducer |

Analyzing Real-Time Data for Predictive Insights

The true magic lies in the predictive insights these sensors provide. Remember the time I dodged a major breakdown because the sensors picked up on a slight anomaly? By analyzing real-time data, they alert you to issues long before they blow up. This foresight allows maintenance teams to schedule fixes at the most opportune times, prolonging equipment life and preventing unscheduled downtime.

Integrating advanced analytics6 with these sensors can amplify their predictive prowess. Machine learning algorithms can forecast failures with pinpoint accuracy, helping you stay one step ahead.

Communicating with Control Systems

These smart sensors aren’t just silent guardians; they’re communicators too. Often linking wirelessly with control systems, they enable remote monitoring and management. This connectivity means alerts are automatically sent when something's amiss, ensuring that your team can respond quickly and decisively.

Leveraging Smart Sensors for Cost Efficiency

Smart sensor technology isn't just about being proactive; it’s also about saving money. By reducing unnecessary inspections and focusing resources where they're truly needed, predictive maintenance saves you from unexpected repair costs and minimizes production halts.

Think about steel wire ropes in heavy machinery: wireless sensors embedded within can send real-time alerts7 about tensile stress or corrosion levels. This prevents catastrophic failures and allows you to optimize maintenance schedules, ensuring everything runs like clockwork.

Smart sensors can predict equipment failures.True

They analyze real-time data to detect anomalies indicating potential failures.

Smart sensors eliminate the need for human monitoring.False

They assist but do not replace human oversight, providing data for decision-making.

Which Industries Benefit Most from Sensor-Enabled Steel Wire Ropes?

Imagine ropes that not only lift but also think! Sensor-enabled steel wire ropes are doing just that, transforming industries with their smart capabilities.

Industries like construction, mining, and marine benefit most from sensor-enabled steel wire ropes due to their ability to provide real-time monitoring and predictive maintenance. These smart ropes enhance safety, minimize downtime, and boost efficiency through continuous data analysis and transmission.

Construction Industry

Have you ever been on a construction site and noticed the incredible amount of machinery at work? I once stood in awe as a crane lifted steel beams high into the sky, realizing that each movement required precision and safety. Sensor-enabled steel wire ropes provide that safety net, offering real-time monitoring8 of load stress. This tech marvel ensures that equipment operates safely, allowing managers to schedule maintenance before things go wrong, saving both lives and dollars.

Key Benefits:

- Enhanced safety standards

- Predictive maintenance capabilities

- Reduced operational disruptions

Mining Sector

Mining is tough work—it's hot, dirty, and dangerous. I've chatted with miners who rely on robust equipment to get their jobs done, and they tell me stories of near-misses that make your heart race. Sensor-enabled ropes in this sector are lifesavers. By monitoring wear and tear, they give early warnings before a rope reaches its breaking point, which reduces unscheduled maintenance and extends equipment life, ultimately enhancing safety9 for workers.

| Benefit | Impact |

|---|---|

| Real-time condition monitoring | Extends equipment life |

| Early failure detection | Increases worker safety |

| Maintenance scheduling | Minimizes operational downtime |

Marine Applications

Out at sea, where the salt air bites into metal like it’s a snack, you need ropes that can withstand the harsh environment. I've always found the ocean both mesmerizing and terrifying—its power is immense. Sensor-enabled steel wire ropes here are crucial; they transmit data about stresses like salinity and tension. In offshore operations, where a single failure can lead to catastrophic outcomes, this technology is a game-changer.

- Corrosion Monitoring: Helps in anticipating material degradation.

- Load Management: Ensures optimal performance10 under varying conditions.

Industrial Manufacturing

Ever watched a factory line in action? It’s like a perfectly choreographed dance of machinery. But behind the scenes, there's a constant battle against wear and tear. I remember visiting a factory floor once and being amazed at how smoothly everything ran—thanks in part to sensor-enabled steel wire ropes. They provide insights into fatigue levels and usage patterns, allowing for better planning of machinery maintenance. This tech leads to fewer unexpected failures, boosting productivity.

Consider exploring further how these ropes contribute to operational efficiency through predictive analytics in industrial settings11.

Sensor-enabled ropes reduce construction downtime.True

Real-time monitoring enables proactive maintenance, minimizing disruptions.

Marine industries don't need sensor-enabled ropes.False

They require corrosion and load monitoring to prevent failures.

How Are Smart Sensors Transforming Industrial Applications?

Imagine a world where machines practically talk to us, predicting their own needs before anything goes wrong. That's the magic of smart sensors in industries today.

Smart sensors in industrial applications provide real-time data collection and analysis, facilitating predictive maintenance, enhanced safety, and optimized operations. Their integration with the Industrial Internet of Things (IIoT) promises to transform industries by improving efficiency and reducing operational costs.

Predictive Maintenance Revolution

I remember the first time I realized the true power of predictive maintenance. It was during a routine visit to a mining site. The engineers there showed me how smart sensors embedded in steel wire ropes were transmitting real-time data about tensile stress12 and wear. The data was like a crystal ball, letting them foresee potential failures before they happened. This kind of foresight drastically cut down on downtime and maintenance costs, and honestly, it was like witnessing a small miracle.

In mining operations, for instance, this technology not only extends the lifespan of equipment but also ensures that safety standards are consistently met. I’ve seen firsthand how this proactive approach can make all the difference in both safety and cost management.

Enhancing Safety Protocols

Safety has always been a top priority in industrial settings. I once spoke with a team working on an offshore oil rig who explained how smart sensors monitored environmental conditions like temperature and humidity. These sensors provided early alerts for potential hazards, which was crucial in preventing accidents in such extreme environments.

What’s even more impressive is how these sensors integrate with IIoT systems13, allowing for comprehensive safety management. Operators receive real-time alerts on their devices, enabling immediate action to address threats. It’s like having an extra set of eyes watching over everything.

Optimizing Operational Efficiency

In the world of manufacturing, I’ve seen smart sensor technology revolutionize operations by providing real-time insights into machinery performance. This level of detail allows managers to make informed decisions that enhance productivity. I once visited a plant where smart sensors automatically adjusted machinery settings based on demand forecasts—a remarkable feat that significantly optimized production rates.

By collecting vast amounts of data, these sensors help industries pinpoint inefficiencies, streamlining operations and reducing waste. I’ve observed how this data-driven approach transforms the way industries operate, making them leaner and more efficient.

| Application | Impact on Industry |

|---|---|

| Mining | Early detection of equipment wear |

| Oil & Gas | Real-time monitoring of hazardous conditions |

| Manufacturing | Optimization of production processes |

| Logistics | Improved tracking and efficiency in supply chains |

The combination of smart sensor technology with advanced analytics14 tools further elevates operational efficiency by delivering actionable insights into complex industrial processes. It's truly an exciting time to witness these advancements firsthand and see the profound impact they're having across various sectors.

Smart sensors reduce industrial downtime by 50%.False

While smart sensors reduce downtime, a 50% reduction is not universally proven.

Smart sensors can detect gas leaks in oil industries.True

Smart sensors monitor for gas leaks, enhancing safety in oil industries.

Conclusion

Smart sensors in steel wire ropes enhance safety and efficiency by providing real-time monitoring, predictive maintenance, and reducing costs, transforming industrial operations across construction, mining, and marine sectors.

-

Explore how real-time monitoring enhances safety and efficiency in construction sites, reducing risk and improving project outcomes. ↩

-

Learn how predictive maintenance optimizes mining operations by minimizing unexpected downtime and extending equipment lifespan. ↩

-

Discover how analyzing sensor data can lead to improved durability and performance of steel wire ropes. ↩

-

Understand the stringent safety standards in Europe that govern the use of steel wire ropes. ↩

-

Find out about the safety regulations in North America impacting steel wire rope usage. ↩

-

Discover how machine learning enhances the accuracy of predictive maintenance through advanced data analysis. ↩

-

Explore how real-time alerts from smart sensors help in preventing costly equipment failures. ↩

-

Real-time monitoring helps construction managers ensure safety by providing instant data on load stress and equipment condition. ↩

-

Learn how smart technology improves safety standards in mining operations by preventing equipment failures. ↩

-

Find out how sensors optimize marine operations by monitoring environmental stresses and ensuring load management. ↩

-

Discover how predictive analytics in industrial settings enhances operational efficiency and reduces machine downtime. ↩

-

Understanding tensile stress monitoring helps in predicting machine failures, reducing downtime and costs. ↩

-

IIoT integration with smart sensors improves safety through real-time data and alerts. ↩

-

Advanced analytics provide actionable insights, streamlining operations and reducing waste. ↩