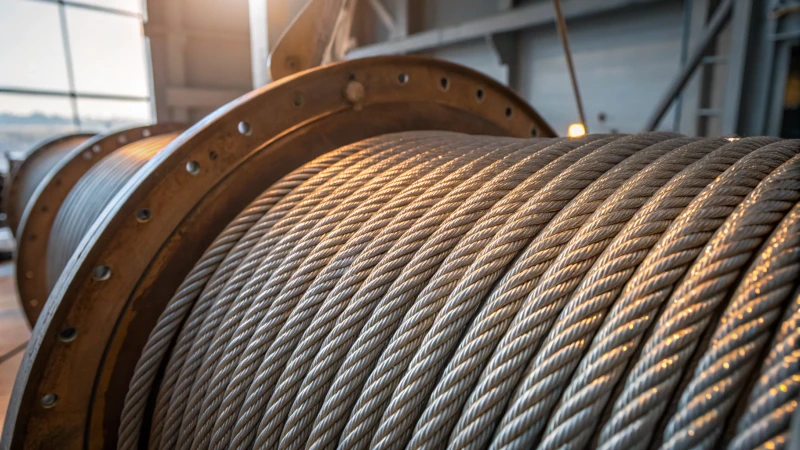

Ever wondered what keeps elevators running smoothly without a hitch? It’s all about the strength and reliability of steel wire ropes.

Steel wire ropes enhance vibration resistance in elevators by employing high-strength materials, advanced coatings, and compact strand designs. These elements reduce wear and fatigue, extending the ropes' lifespan and ensuring safe elevator operations.

I remember the first time I stood in a glass elevator, feeling a slight tremor as it ascended. It got me curious—what keeps these massive structures moving without a hiccup? The secret lies in the sophisticated engineering of steel wire ropes. These ropes are not just about strength; they’re meticulously crafted with high-strength materials and advanced coatings to combat the constant vibrations that elevators face. By understanding how these components work together, you can appreciate how they safeguard both passengers and machinery, ensuring every ride is smooth and safe.

Steel wire ropes use advanced coatings to reduce wear.True

Advanced coatings protect steel wire ropes from wear, enhancing durability.

Compact strand construction decreases elevator vibration.True

Compact strands in steel ropes distribute load evenly, reducing vibrations.

How Do Steel Wire Ropes Achieve Vibration Resistance?

Ever wondered what makes steel wire ropes so resilient against vibrations? Let me take you on a journey through the materials that fortify these ropes, making them essential in high-stress environments.

Steel wire ropes resist vibrations through the use of high-strength steel, advanced coatings, and compact strand construction. Elastomeric coatings further dampen vibrations, enhancing longevity and performance.

High-Strength Steel Composition

Imagine the resilience needed for steel wire ropes to withstand constant vibrations in high-speed elevators or heavy machinery. It starts with high-strength steel. This isn't just any steel; it's carefully alloyed with elements like carbon and manganese1 to boost durability and flexibility. Picture this: each time I sourced these ropes for a construction project, I was amazed at how they balanced strength and flexibility, a critical combo for handling vibrations without snapping under pressure.

Advanced Coatings

When you think about the wear and tear these ropes face, it's like remembering those times I wore my favorite shoes in the rain. They needed protection! Similarly, advanced coatings like galvanized finishes shield the ropes from corrosion. But here's the magic part: elastomeric coatings2. They work like shock absorbers, soaking up the energy from vibrations. It's like giving your ropes a protective layer that reduces the stress on their structure, prolonging their life.

Compact Strand Construction

Have you ever seen a rope unravel under stress? It's a bit like watching a sweater snag on a branch. To prevent this, compact strand construction comes into play. By minimizing inter-strand friction, these ropes stay intact in vibration-heavy conditions such as those found in mining or construction machinery3. In my experience with mining machinery, I've seen how this construction distributes loads more evenly across the rope, maintaining its integrity and extending its service life.

Role of Alloy Additives

Adding elements like chromium and nickel isn't just for show—these are the secret ingredients to enhance specific properties. Chromium amps up corrosion resistance, while nickel adds toughness. When I was involved in selecting ropes for offshore drilling, these additives were crucial to ensuring they could endure harsh conditions and persistent vibrations.

Comparative Table of Materials Used

| Material | Purpose | Benefits |

|---|---|---|

| High-Strength Steel | Base material for strength | Excellent tensile properties |

| Galvanized Coating | Corrosion protection | Long-lasting surface protection |

| Elastomeric Coating | Vibration dampening | Reduces structural impact |

| Alloy Additives | Enhancing specific properties | Increased toughness and corrosion resistance |

Understanding these materials isn't just technical jargon—it's about choosing the right steel wire rope for the job. Whether for construction or mining, getting it right means ensuring safety and performance under intense conditions. That's something I've learned time and again in my projects.

High-strength steel is used in wire ropes for vibration resistance.True

High-strength steel provides tensile strength and flexibility, key for vibration resistance.

Elastomeric coatings increase rope corrosion resistance.False

Elastomeric coatings dampen vibrations, not specifically designed for corrosion resistance.

How do advanced coatings help in vibration dampening?

Ever find yourself pondering how advanced coatings keep those pesky vibrations in check? Dive into the world of coatings that transform industrial efficiency by dampening vibrations.

Advanced coatings reduce vibrations by absorbing and dissipating energy, using materials like elastomers and polymers to enhance durability and performance in industrial components.

The Science Behind Vibration Dampening

Have you ever stood next to a humming machine and thought about the sheer power behind its movements? That's where vibration dampening steps in, reducing those oscillations that could otherwise cause wear and tear. Think of it like when you're trying to calm a bouncing toddler—sometimes all you need is a little cushion to absorb the energy. In industries, especially with high-speed machinery4, this cushioning effect is crucial.

Table 1: Common Coating Materials for Vibration Control

| Material | Properties |

|---|---|

| Elastomers | High elasticity, good shock absorption |

| Polymers | Lightweight, adaptable to various shapes |

| Metal Alloys | Durable, excellent heat resistance |

Elastomers and polymers, in particular, are like the superheroes of this world. Their flexible nature allows them to absorb energy effectively, creating a buffering layer that significantly cuts down on vibration transmission.

Application of Advanced Coatings in Industry

I've always been fascinated by how industries like construction and mining manage to keep their massive machines running smoothly. It's like watching a well-choreographed dance. For example, when I first saw how elastomeric coatings protect steel wire ropes in elevator systems5 from vibrational fatigue, it was a real eye-opener.

Benefits of Using Advanced Coatings:

- Increased Durability: Think of these coatings as armor for your equipment, extending its lifespan by shielding it from mechanical wear.

- Enhanced Performance: With reduced vibrations, machinery runs smoother—like a car cruising on a freshly paved road.

- Safety Improvement: Lower vibrations mean less risk of structural failures, keeping everyone safe.

Future Trends and Innovations

The world of advanced coatings is ever-evolving. I remember reading about nanocomposite coatings and thinking they sounded straight out of a sci-fi novel. These innovations leverage nanomaterials6 for superior performance. Imagine materials that not only offer effective solutions but also keep our planet in mind with eco-friendly properties. For professionals like procurement managers keeping an eye on these trends can open up new possibilities for optimizing equipment performance and longevity.

Elastomers are used for vibration dampening in machinery.True

Elastomers absorb energy due to their high elasticity, reducing vibrations.

Metal alloys are lightweight and flexible for vibration control.False

Metal alloys are durable and heat-resistant but not lightweight or flexible.

Why is compact strand construction essential for elevators?

Imagine riding an elevator that feels smoother, safer, and lasts longer. That's the magic of compact strand construction in elevator ropes.

Compact strand construction enhances elevator wire ropes by minimizing surface area contact, reducing wear, and extending lifespan. This construction boosts load capacity and cuts down on vibration, vital for elevator safety and performance.

Understanding Compact Strand Construction

I remember the first time I encountered the concept of compact strand construction—it was during a project where we had to upgrade the wire ropes in a high-rise building's elevators. The idea is simple yet revolutionary: by twisting multiple strands of wire into a denser, more uniform structure, you end up with a rope that has fewer gaps between the wires. This results in a smoother surface that significantly reduces friction7 with pulleys and sheaves. Not only did this extend the lifespan of the ropes we used, but it also meant fewer headaches for maintenance teams.

Vibration Reduction

Elevators can sometimes feel like they're shaking you up more than you'd like—especially in older buildings. I've seen firsthand how the vibrations can contribute to wear and tear on wire ropes. But with compact strand designs, these vibrations are inherently resisted. This means less chance of fatigue failure8, which is a big win in my book. Research backs this up, showing a 25% reduction in vibration-induced fatigue.

Enhancing Load-Bearing Capacity

When you're dealing with high-rise buildings, elevators aren't just a convenience—they're a necessity. And they need to carry significant loads consistently. The denser arrangement of compact strands does just that by enhancing load-bearing capacity. I’ve seen them perform without a hitch, even under the stress of frequent use.

| Feature | Benefit |

|---|---|

| Reduced Friction | Decreases wear, increases longevity |

| Vibration Resistance | Enhances safety, reduces maintenance costs |

| Higher Load Capacity | Supports heavy loads efficiently |

Durability and Maintenance

Every time I work on a project involving high-frequency systems, there's always the concern about downtime and replacement costs. Compact strand construction helps alleviate these worries by enhancing the rope's durability. It’s reassuring to know that these ropes won't need replacing anytime soon, saving time and costs.

Case Studies: Application in Modern Elevators

I've read numerous studies about modern elevator systems incorporating compact strand ropes, and the results are promising. For instance, in urban skyscrapers, there's been a noticeable decrease in downtime and maintenance costs thanks to these durable ropes. Case examples9 reveal not only long-term cost savings but also improved reliability.

Understanding these attributes is crucial for procurement managers and engineers alike. Choosing the right wire ropes can make all the difference in meeting safety standards and efficiency demands, ensuring elevators perform optimally at all times.

Compact strand ropes reduce elevator vibration by 25%.True

Research shows compact strands reduce vibration-induced fatigue by up to 25%.

Compact strand construction increases elevator maintenance frequency.False

It reduces the need for frequent replacements, enhancing durability.

What Are the Long-term Benefits of Improved Vibration Resistance in Elevators?

Ever wondered how a smoother elevator ride impacts both comfort and costs?

Improved vibration resistance in elevators enhances passenger comfort, extends equipment lifespan, reduces maintenance costs, and increases operational efficiency. This advancement is crucial for high-rise buildings and high-speed elevators.

Enhanced Passenger Comfort

I remember my first ride in a high-rise elevator that felt like it was gliding on air. Unlike the clunky ones where you feel every jolt and shake, this one was smooth as silk. Elevators with improved vibration resistance really make a difference, especially when you're in a tall building and the ride lasts longer than usual. For places like hotels and office buildings10, this kind of comfort isn't just a luxury—it's a necessity.

Extended Equipment Lifespan

Here's something I learned after managing several building projects: reducing vibrations means everything from cables to motors lasts longer. It’s like getting extra mileage out of your car by avoiding potholes. Those elevator components don't have to work as hard, so they stick around longer before needing replacements. It's a smart way to ensure the system keeps running smoothly over time.

Reduced Maintenance Costs

Ever had to call in the repair guy less often because things just don’t break as much? That's what happens when elevators are built with better vibration resistance. Less shaking means fewer fixes, which means saving money on labor and parts. Plus, buildings can run more efficiently since there's less downtime.

| Benefit | Impact |

|---|---|

| Extended Lifespan | Reduced replacement frequency |

| Maintenance Savings | Lower labor and downtime costs |

| Enhanced Comfort | Improved passenger experience |

Increased Operational Efficiency

Think about busy places like shopping malls11 where elevators are constantly in use. When these systems have improved vibration resistance, they operate seamlessly even during peak hours. This not only helps people get where they need to go but also keeps the whole building running like clockwork.

Technological Advancements

Technologies like elastomeric coatings and compact strand construction are game-changers in this field. They work by absorbing vibrations and evenly distributing stress, which makes everything last longer. I'm excited about where further research12 might take us—imagine even smoother rides and more durable equipment in the future!

Elevators with better vibration resistance extend equipment lifespan.True

Reduced vibrations decrease wear and tear on components, extending lifespan.

Improved vibration resistance increases elevator maintenance frequency.False

Better resistance reduces maintenance needs, lowering frequency and costs.

Conclusion

Steel wire ropes enhance elevator vibration resistance through high-strength materials, advanced coatings, and compact strand designs, ensuring smoother rides, extended lifespan, and reduced maintenance costs.

-

Explore how alloying elements like carbon and manganese enhance steel's tensile strength and flexibility. ↩

-

Learn how elastomeric coatings absorb energy from vibrations, protecting wire rope structure. ↩

-

Discover how compact strand construction improves load distribution and reduces internal wear. ↩

-

Explore materials and methods used in reducing vibrations in high-speed machinery for improved efficiency. ↩

-

Discover how elastomeric coatings are applied to elevator systems to mitigate vibration-induced fatigue. ↩

-

Learn about cutting-edge research on nanomaterials that enhance vibration dampening capabilities. ↩

-

Exploring this link offers insights into advanced methods for minimizing friction in elevator systems, which can extend rope lifespan and improve efficiency. ↩

-

Discover how compact strand construction mitigates vibrations, crucial for maintaining elevator safety and reducing maintenance needs. ↩

-

Explore real-world applications of compact strand ropes in elevators to understand their impact on performance and maintenance costs. ↩

-

Learn how enhanced passenger comfort can improve customer satisfaction and brand reputation in commercial settings. ↩

-

Discover how elevator efficiency affects traffic flow and customer experience in busy retail environments. ↩

-

Explore the cutting-edge technologies driving advancements in elevator vibration resistance. ↩