Imagine steel wire ropes that not only withstand the test of time but also thrive in the harshest environments.

Surface treatment customization enhances steel wire ropes by boosting their corrosion resistance, wear resistance, and tensile strength. Techniques like hot-dip galvanizing, electro-galvanizing, and advanced coatings extend the lifespan and reliability of ropes in tough conditions.

Back when I first started exploring the world of industrial materials, I was amazed at how surface treatments could revolutionize a simple steel wire rope. These techniques aren't just fancy add-ons; they fundamentally alter how these ropes perform. Whether you need them to last longer in salty sea air or withstand heavy abrasion in a bustling construction site, customizing the surface treatment can make all the difference. By tailoring treatments to specific needs, we not only enhance durability but also ensure safety and efficiency in demanding environments. Let’s dive into how these treatments work and why they’re a game-changer.

Hot-dip galvanizing enhances corrosion resistance.True

Hot-dip galvanizing adds a protective zinc layer, reducing rust.

Electro-galvanizing reduces tensile strength of ropes.False

Electro-galvanizing does not reduce tensile strength; it protects against corrosion.

What Are the Key Surface Treatment Technologies?

Ever wondered how the world around us stays so durable and pristine?

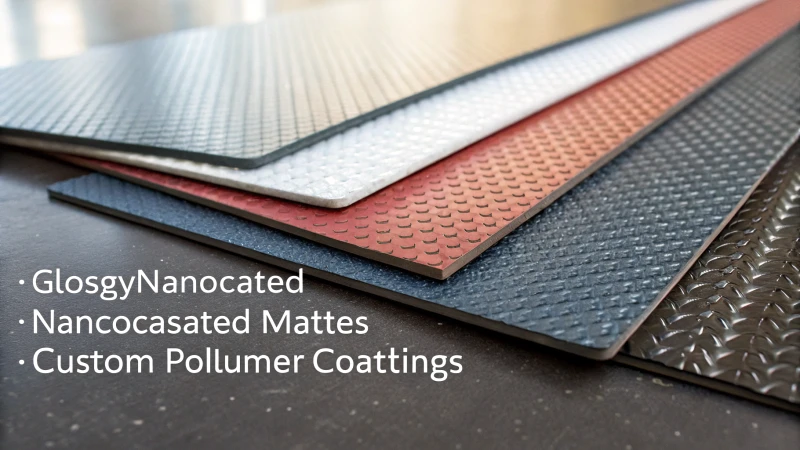

Key surface treatment technologies include hot-dip galvanizing, electro-galvanizing, nanocoatings, and polymer coatings. Each offers unique benefits like corrosion resistance, wear resistance, and enhanced durability.

Transition: Why Surface Treatments Matter

Have you ever considered how materials withstand the test of time, weather, and constant use? It’s something I often marvel at, especially when I think about the forces these materials have to resist daily. Whether it’s ensuring the bridges we drive over or the cars we drive in remain safe and reliable, surface treatments are the unsung heroes.

Hot-Dip Galvanizing

Take hot-dip galvanizing, for example. Imagine dipping steel into a molten zinc bath—a bit like giving it a protective armor. I picture it like dressing up a soldier in robust gear before battle. This method is a lifesaver in salty coastal areas, providing up to 20 years of protection.

| Advantages | Applications |

|---|---|

| Long-lasting protection | Coastal infrastructure |

| Cost-effective | Marine industry |

Electro-Galvanizing

Then there’s electro-galvanizing. It’s a bit like painting with electricity—an electric current smooths a zinc coat onto the metal. I remember the first time I learned about this; it felt like discovering a new art form! Perfect for those sleek automotive finishes.

| Benefits | Industries |

|---|---|

| Smooth, uniform coating | Automotive |

| Reduced material weight | Electronics |

Nanocoatings

Nanocoatings are like superheroes in tiny form. They resist corrosion and wear with their superhydrophobic powers. Working in environments filled with harsh chemicals? These coatings are your best friend.

- Key Features:

- Enhanced chemical resistance

- Lightweight protection

Learn more about nanocoatings1 and their industrial applications.

Polymer Coatings

And let’s not forget polymer coatings—flexible, UV-resistant, and perfect for anything braving the great outdoors. Think of them as the sunscreen for your outdoor equipment.

- Usage Examples:

- Outdoor machinery

- Building exteriors

For more insights, explore how polymer coatings2 can enhance material properties.

Quality Control & Certification

Of course, none of this matters without quality control. Picture it as ensuring every piece of armor is perfectly fitted and tested—rigorous testing like ASTM B117 for corrosion is crucial.

- Testing Parameters:

- Salt spray test (>500 hours)

- Friction coefficient verification (<0.4)

Understanding the importance of quality control3 can help in selecting the right surface treatment technology.

Hot-dip galvanizing provides a uniform zinc coating.False

Electro-galvanizing, not hot-dip, provides a uniform finish.

Nanocoatings are useful in harsh chemical environments.True

Nanocoatings enhance chemical resistance, ideal for such settings.

Why Do Coating Thickness and Uniformity Matter?

Ever wondered why the thickness and uniformity of a coating matter so much?

Coating thickness and uniformity are crucial for a material's performance because they affect its durability, corrosion resistance, and wear protection. Ensuring the right thickness provides essential protection, while consistent application avoids weak spots that can cause early failure.

The Role of Coating Thickness

I remember when I first dived into the world of coatings in my career, it was quite an eye-opener. I learned that in many industries, getting the thickness just right is like finding the perfect recipe for grandma’s secret sauce—it makes all the difference! The right coating thickness not only shields against environmental factors4 like moisture and chemicals but also boosts mechanical properties. Take for instance the time I worked on a project where we needed thicker coatings for durability. It was great for protection, but balancing the added weight was a bit tricky.

Table: Recommended Coating Thickness for Various Applications

| Application | Recommended Thickness (μm) |

|---|---|

| Marine Environments | 60-100 |

| Construction Machinery | 50-80 |

| Automotive Parts | 30-50 |

| Consumer Electronics | 10-30 |

Importance of Coating Uniformity

Uniformity in coatings is akin to spreading butter evenly on your toast. I once faced a situation where non-uniform coating led to rusting way too quickly in a high-salinity environment. It taught me that even small inconsistencies can have big impacts, especially in demanding conditions. Plus, when it comes to consumer products, a uniform coating ensures everything looks as good as it performs, which is something we all appreciate.

Technological Advances in Coating Application

Thanks to modern technology, applying coatings has become more precise than ever. I still remember trying out electrostatic spray deposition5 for the first time—it felt like magic seeing how evenly it distributed the coating, minimizing those pesky human errors. In sectors like automotive or aerospace, achieving such uniformity can significantly improve fuel efficiency by reducing drag.

Coating Thickness and Durability: A Balanced Approach

Finding that sweet spot between thickness and durability is like walking a tightrope. Thicker coatings often mean better protection, but they also come with trade-offs like increased cost or weight. I’ve seen industries rely heavily on standards like ASTM or ISO to navigate these challenges, ensuring they strike the right balance for their specific needs.

In the end, coating thickness and uniformity aren't just about adding a protective layer; they're integral to how materials perform and last across various industries. It's fascinating how ongoing research keeps refining these aspects, bringing us closer to even better solutions for future applications.

Thicker coatings always improve durability.False

While thicker coatings can enhance durability, they may add weight or reduce flexibility.

Uniform coatings prevent premature failure.True

Uniform coatings ensure consistent protection, reducing susceptibility to corrosion and wear.

What Exciting Innovations Are Shaping Surface Treatment?

Ever wondered how surface treatments are evolving to meet modern challenges? Let’s dive into the fascinating world of cutting-edge innovations that promise enhanced durability and sustainability. From nanocoatings to advanced polymers, the possibilities are endless.

Innovations in surface treatment like nanocoatings and advanced polymer coatings are enhancing durability and performance by providing chemical resistance, UV protection, and customization for specific environments.

Nanocoatings: A Game Changer

I remember the first time I encountered nanocoatings; it was like stepping into a sci-fi movie. These tiny wonders offer superhydrophobic properties, significantly boosting resistance to chemical corrosion. Imagine extending the life of your materials by 50% just by applying this invisible shield! My first experience involved a simple salt spray test, which dramatically showcased the coating's potential—turning skeptics into believers.

Advanced Polymer Coatings

Working in the field, I've seen how harsh sunlight can wreak havoc on materials. Enter advanced polymer coatings, which provide robust wear and UV resistance. They're perfect for outdoor applications, especially in high-stress environments like construction and marine industries. Think of them as sunscreen for your surfaces—a layer that not only protects but enhances durability.

| Polymer Coating Benefits | Application |

|---|---|

| UV Resistance | Outdoor |

| Wear Resistance | Industrial |

Customization of Coating Techniques

Customization is the name of the game when it comes to meeting specific needs. Whether you're dealing with a high-stress industrial environment or just want an extra thick layer of protection, being able to adjust the coating thickness is a game-changer. I once worked on a project where we needed a 100μm thick coating to withstand intense conditions—it was customized perfection.

Coating Customization6 ensures durability and aligns with industry standards.

Quality Control and Certification

Ensuring quality in surface treatments isn't just about applying a coat and calling it a day. It involves rigorous testing and certifications like ASTM B117, which ensures coatings can endure over 500 hours in harsh conditions. I've always been fascinated by the meticulous process of friction coefficient testing—it’s critical for verifying wear resistance and gives me peace of mind knowing the product will perform reliably.

Quality Certification7 processes are integral to meeting international standards and ensuring product reliability.

These innovations aren't just about improving performance—they're setting new standards for sustainability and efficiency in material science. With advanced technologies and customization techniques, the future of surface treatment is brighter than ever, offering unprecedented advancements in durability and application potential. Whether you’re in construction, marine, or industrial sectors, these innovations are paving the way for a more sustainable and efficient future.

Nanocoatings improve corrosion resistance by 50%.True

Salt spray tests show nanocoatings extend corrosion resistance by 50%.

Advanced polymer coatings lack UV resistance.False

Advanced polymer coatings provide robust UV resistance for outdoor use.

Why is Quality Control Crucial in Customized Surface Treatments?

Have you ever wondered why surface treatments are more than just a coat of paint?

Quality control in customized surface treatments is essential because it guarantees the right coating thickness, uniformity, and compliance with safety standards, which ultimately enhances performance and durability across various environments.

The Importance of Consistent Coating Thickness

I remember when I first delved into the world of customized surface treatments, the concept of coating thickness seemed almost trivial. But let me tell you, achieving that perfect 30-60μm for general use isn't just a guideline—it's a game-changer. For special needs, going up to 100μm can be crucial. Just like putting on the right layer of sunscreen before hitting the beach, this precision ensures your equipment is protected against corrosion and wear. It's a bit like baking; too much or too little can throw everything off.

| Environment | Recommended Coating Thickness |

|---|---|

| Coastal | 60-100μm |

| Industrial | 30-60μm |

| Marine | 80-100μm |

Uniformity and Durability

Think of uniformity in coating like applying makeup. You want it even, without missing spots that could turn into embarrassing "weak points" on your product. That's why multi-point uniformity testing is non-negotiable—it's how we ensure every inch of the surface is protected and ready to take on whatever the world throws at it.

Learn more about performance8 under stress in high-wear environments.

Adherence to Safety Standards

When it comes to safety standards, like ASTM B117 for salt spray testing, it's all about peace of mind. Imagine knowing your product can withstand over 500 hours of grueling tests—that’s like knowing your umbrella won’t flip inside out during a storm. Such rigorous testing means your equipment will stand tall against real-world stresses.

The Role of Innovative Technologies

Innovation in surface treatment is akin to upgrading from a flip phone to a smartphone. Advanced technologies like nanocoatings can enhance resistance by up to 50%. Embracing these advancements in quality control ensures our products are not just meeting but exceeding modern demands.

Friction Coefficient Testing

Testing friction coefficients may sound technical, but it’s just making sure your moving parts glide smoothly without wearing out prematurely. Keeping that coefficient below 0.4 ensures efficiency and longevity, which in turn means less maintenance and downtime—a win-win for any industry.

Learn more about quality control in surface treatments9 and discover how these processes affect industries by exploring detailed reports and case studies available online.

Coating thickness over 100μm is standard for all applications.False

Coating thickness over 100μm is only required in special scenarios.

ASTM B117 requires coatings to withstand 500 hours of testing.True

ASTM B117 salt spray test ensures coatings endure harsh conditions.

Conclusion

Surface treatment customization significantly enhances steel wire ropes' durability, corrosion resistance, and performance through techniques like galvanizing and advanced coatings, tailored for specific industrial environments.

-

Explore how nanocoatings provide superior protection against chemicals and environmental factors. ↩

-

Discover the benefits of polymer coatings in enhancing outdoor material durability. ↩

-

Learn why stringent quality control is crucial for effective surface treatments. ↩

-

Discover how appropriate coating thickness enhances protection against environmental elements like moisture and chemicals. ↩

-

Explore this advanced technology that ensures even coating distribution across surfaces. ↩

-

Explore techniques for customizing coating thickness to enhance product durability. ↩

-

Learn about essential certifications ensuring high-quality surface treatments. ↩

-

Discover why uniformity is key to maintaining durability and performance in surface coatings. ↩

-

Explore comprehensive insights into quality control processes for various industries. ↩