Ever wondered how steel wire ropes are evolving to meet the demands of modern crane operations?

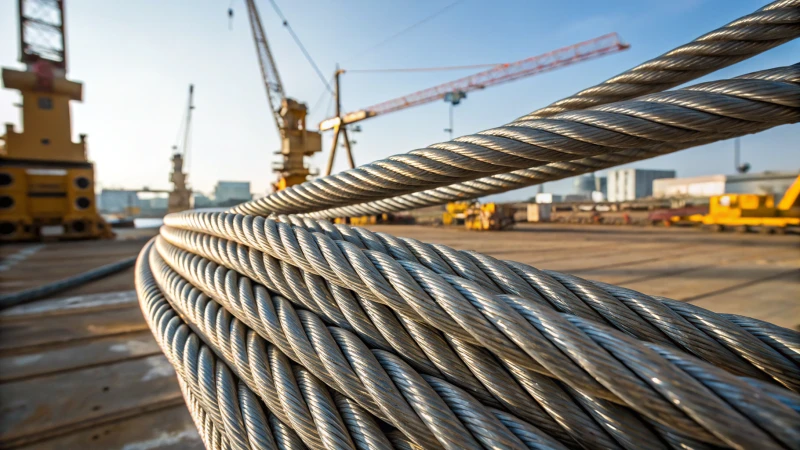

Recent advancements in steel wire rope technology are making them lighter, stronger, and more durable, which is essential for the increasing automation in crane operations. By enhancing materials and manufacturing processes, these ropes now meet rigorous safety and performance standards.

As someone deeply involved in the procurement process, I know firsthand how crucial it is to stay ahead of these technological trends. I've seen projects where the right choice of wire ropes made all the difference—not just in safety and efficiency but also in cost-effectiveness. Understanding these innovations can truly be a game-changer for anyone responsible for sourcing materials that keep projects running smoothly. Let's explore how these advancements are setting the stage for the future of crane operations, ensuring reliability and enhanced performance on-site.

Steel wire ropes are now lighter and stronger.True

Innovations focus on making ropes lighter and stronger for efficiency.

Automated cranes do not require enhanced wire ropes.False

Automated cranes demand ropes that meet higher safety and performance standards.

How are material innovations enhancing steel wire ropes?

Have you ever wondered how steel wire ropes are becoming tougher and more versatile?

Material innovations in steel wire ropes include advancements in alloy compositions, coating techniques, and manufacturing processes. These improvements enhance durability, strength, and corrosion resistance, enabling the ropes to meet high-performance demands in various industries.

Advanced Alloy Compositions

I remember when I first learned about the impact of advanced alloys on steel wire ropes. It was like discovering a hidden superpower! These new alloy compositions, especially with micro-alloyed steel, boost tensile strength and flexibility. Imagine ropes that can lift heavier loads while maintaining safety! Adding elements like chromium or nickel significantly enhances corrosion resistance1, a game-changer for marine and mining environments where harsh conditions are the norm.

Innovative Coating Techniques

In my journey through industrial innovations, one thing stands out: the magic of coatings. Picture this: a layer of zinc from galvanization wraps around steel, acting like armor against rust and corrosion. Then there are polymer coatings, like PVC and nylon, which not only shield from environmental damage but also reduce mechanical wear. These coatings can be customized for specific needs, whether it's resisting chemicals or minimizing friction during operation. I invite you to explore more about coating benefits2 and see how they amplify durability.

Manufacturing Process Enhancements

Manufacturing processes have always fascinated me, especially when they evolve with precision spinning and heat treatment technologies. These innovations ensure the uniformity and strength of steel wire ropes. Precision spinning tightly weaves individual strands into a robust product, while heat treatment alters the steel's microstructure, making it more resilient to fatigue and stress. This is like fine-tuning an instrument to achieve perfect harmony! Discover how these processes boost material strength3.

Table: Innovations at a Glance

| Innovation Type | Benefit |

|---|---|

| Advanced Alloys | Increased tensile strength and flexibility |

| Innovative Coatings | Enhanced corrosion and wear resistance |

| Manufacturing Processes | Improved uniformity and material resilience |

Applications Across Industries

These innovations are reshaping industries where reliability is non-negotiable. In construction, stronger yet lighter ropes allow cranes to function more efficiently. Meanwhile, in mining, enhanced corrosion resistance ensures that ropes withstand the demanding underground environments longer. See how these advancements are improving operational efficiencies across various industries4.

Future Trends in Steel Wire Ropes

Looking ahead, material science promises even more exciting breakthroughs. With researchers delving into nanotechnology5, we can anticipate coatings offering unprecedented protection and efficiency. Keeping up with these trends ensures that operations are optimized with the latest advancements.

Advanced alloys increase steel wire ropes' tensile strength.True

Micro-alloyed steel enhances tensile strength and flexibility.

Polymer coatings decrease corrosion resistance of steel ropes.False

Polymer coatings like PVC enhance corrosion resistance.

How is Automation Driving the Demand for Advanced Steel Wire Ropes?

Automation is not just a buzzword; it's reshaping industries and upping the ante on steel wire ropes. As I dive into this transformation, you'll see why these ropes are becoming indispensable.

Automation boosts efficiency and safety, driving up demand for advanced steel wire ropes. These ropes' strength and durability make them essential in automated systems like cranes and elevators.

Enhanced Efficiency and Precision

Remember the first time you saw a crane in action? I was mesmerized by its sheer power and precision. Automation in such operations demands components that can handle repetitive cycles and massive loads. Advanced steel wire ropes offer the strength and flexibility6 needed to keep these machines running smoothly. They endure tough conditions without missing a beat, making them invaluable.

Safety Standards and Compliance

Safety has always been a top priority for me, especially after witnessing an incident on a construction site. Automation magnifies these concerns, and advanced steel wire ropes rise to the challenge, meeting rigorous safety standards. This reliability is crucial in sectors like construction and mining7, where equipment failures can have dire consequences.

| Feature | Benefit |

|---|---|

| High tensile strength | Handles heavy loads effectively |

| Corrosion resistance | Suitable for harsh environments |

| Flexibility | Adapts to various applications |

Cost Efficiency and Longevity

The upfront cost of automation can be daunting, but I've found that the long-term savings are worth it. Advanced steel wire ropes contribute by minimizing maintenance costs and reducing downtime. They're built to last and deliver consistent performance, providing a solid return on investment over time.

Real-World Applications

Industries such as logistics and marine are riding the automation wave. I've seen advanced steel wire ropes in action in automated conveyor systems8 and hoisting equipment, where their unique properties enhance system efficiency.

Automation isn't slowing down, and neither is the demand for these robust materials.

Advanced steel wire ropes improve crane efficiency.True

They endure frequent cycles and heavy loads, enhancing operational efficiency.

Automation reduces the need for safety standards in mining.False

Increased automation heightens safety concerns, necessitating strict standards.

Why is Durability Crucial in Steel Wire Ropes for Crane Operations?

Imagine the heart-pounding moment when a crane lifts a massive load—durability in steel wire ropes is what stands between success and disaster.

Durability in steel wire ropes for crane operations is essential because it ensures safety, minimizes maintenance costs, and boosts efficiency. These ropes must endure heavy loads, harsh environments, and wear over time to prevent accidents and failures.

I remember standing on a construction site, watching a crane hoist what seemed like a mountain of steel beams. The tension in the air was palpable, not just from the wires but from everyone involved. You see, the durability of those steel wire ropes wasn't just a technical specification—it was the silent promise of safety.

Understanding Durability in Steel Wire Ropes

Durability refers to the rope's ability to withstand stress and adverse conditions without significant deterioration. In crane operations, this means enduring heavy loads9, frequent use, and exposure to varying environmental factors such as moisture and temperature changes.

Material Composition and Its Impact

The type of steel used significantly influences the rope's durability. Stainless steel and galvanized ropes provide different levels of corrosion resistance. Innovations in material science have led to stronger steel alloys10 that enhance longevity.

| Rope Type | Key Feature | Best Use Case |

|---|---|---|

| Stainless | Corrosion Resistant | Marine & Coastal Projects |

| Galvanized | Cost-Effective | General Construction |

The Role of Maintenance in Extending Lifespan

Regular inspection and maintenance practices play a crucial role in extending the lifespan of steel wire ropes. Detecting wear early can prevent failures. Implementing preventive maintenance strategies11 helps manage wear and ensures consistent performance.

Safety Implications of Durable Ropes

The safety of crane operations heavily relies on the integrity of the wire ropes. Durable ropes minimize the risk of accidents caused by unexpected breaks or failures. Adhering to safety standards and conducting regular testing can ensure the ropes meet the required durability thresholds.

Cost Efficiency Through Durability

Investing in durable steel wire ropes may seem costly initially but results in long-term savings12 by reducing the frequency of replacements and minimizing downtime due to rope failures. This cost-efficiency is particularly beneficial in large-scale projects where delays are costly.

Understanding these aspects of durability will aid procurement managers and engineers in selecting the right ropes for their specific crane applications. Each factor—from material choice to maintenance—plays a vital role in ensuring that crane operations remain safe, efficient, and cost-effective.

Stainless steel ropes are best for marine projects.True

Stainless steel ropes offer high corrosion resistance, ideal for marine environments.

Galvanized ropes are more expensive than stainless ones.False

Galvanized ropes are cost-effective, making them cheaper than stainless steel options.

How Do Safety Standards Influence Steel Wire Rope Design?

Ever wondered how steel wire ropes manage to bear such immense loads without snapping? The secret lies in the safety standards that guide their design, ensuring they meet rigorous demands across various industries.

Safety standards influence the design of steel wire ropes by defining material strength, construction methods, and testing procedures. These standards ensure ropes are safe for required load capacity, durability, and environmental conditions.

I remember the first time I saw a crane lifting an enormous steel beam effortlessly into the air. It was mesmerizing, yet slightly terrifying. But then I learned that behind every successful lift is a complex web of safety standards ensuring that steel wire ropes can withstand such tremendous tasks. Let's dive deeper into how these standards shape the very design of these ropes.

The Role of Material Specifications

Whenever I think about material specifications, I recall a project where we had to replace old wire ropes on a construction site. The specifications were our guiding light. Safety standards like those from OSHA or ISO define exactly what materials can be used, ensuring that the tensile strength is up to par with the demands of heavy-duty applications. Imagine being told that a rope can hold your weight while knowing it's been tested to hold the weight of ten elephants—that’s the assurance these standards provide.

Table: Common Material Specifications

| Standard | Tensile Strength (MPa) | Coating Type |

|---|---|---|

| OSHA | 1770 | Galvanized |

| ISO | 1960 | Stainless |

Construction Techniques and Standards

It's fascinating how something as mundane as wire diameter can be crucial. I once witnessed a debate between engineers about the best lay pattern for a specific task. The number of strands and wires per strand, like in a 6x19 classification13, are carefully chosen according to standards to ensure reliability in demanding environments like construction cranes.

Testing Procedures and Compliance

Before any steel wire rope can be trusted to hold, say, a ton of steel above your head, it must pass stringent testing procedures. I vividly remember watching these tests in action and feeling the tension in the room as the ropes were pushed to their limits. These tests ensure compliance with required load capacities and durability under extreme conditions14.

Environmental Considerations

I’ve always admired how even environmental factors like corrosion resistance and temperature extremes are considered in safety standards. When working on projects near saltwater or in scorching heat, knowing that the ropes have been designed with these conditions in mind is reassuring. Standards help determine15 the appropriate adaptations, whether it's through special coatings or materials.

OSHA standards require 1770 MPa tensile strength for wire ropes.True

OSHA specifies a tensile strength of 1770 MPa for wire ropes to ensure safety.

Steel wire ropes with six strands have 19 wires per strand.True

The 6x19 classification indicates six strands, each with 19 wires.

Conclusion

Recent innovations in steel wire ropes enhance their strength, durability, and efficiency, crucial for modern crane operations amid increasing automation and safety demands across various industries.

-

Learn how adding chromium or nickel enhances the corrosion resistance of steel wire ropes, crucial for marine applications. ↩

-

Understand how polymer coatings like PVC and nylon protect against environmental damage and mechanical wear. ↩

-

Discover how heat treatment improves material strength, making steel wire ropes more resilient to fatigue. ↩

-

Explore how various industries utilize enhanced steel wire ropes for improved operational efficiencies. ↩

-

Find out how nanotechnology is leading to innovative coatings offering superior protection for steel wire ropes. ↩

-

Explore why advanced steel wire ropes are essential in high-load, automated applications. ↩

-

Learn about the critical role of steel wire ropes in these sectors, emphasizing safety. ↩

-

Understand how these ropes enhance efficiency and reliability in logistics operations. ↩

-

Understanding load capacity helps ensure the selection of ropes that can handle expected weights without compromising safety. ↩

-

Exploring new steel alloys can reveal advancements that enhance rope strength and durability. ↩

-

Preventive maintenance ensures prolonged rope life, reducing unexpected failures and enhancing safety. ↩

-

Understanding cost benefits of durability helps justify initial investments in high-quality ropes. ↩

-

This link explains the significance of the 6x19 classification in wire rope design. ↩

-

Explore this link to understand the various testing procedures for steel wire rope compliance. ↩

-

Discover how safety standards adapt steel wire rope designs to different environmental challenges. ↩