Ever felt like you're juggling numbers and materials to find the perfect fit for your manufacturing needs?

Opting for high-quality steel wire ropes in automotive manufacturing comes with significant cost advantages. Although the initial expense is higher, these ropes minimize downtime and reduce maintenance costs, ultimately saving up to 20% on operational expenses over time. Their robustness and dependability make them a wise investment for long-term efficiency.

I remember when I first considered switching to steel wire ropes. The upfront costs were daunting, but after crunching the numbers and speaking with industry peers, it became clear that the long-term savings were undeniable. Steel wire ropes not only last longer but also demand less maintenance, which means fewer headaches and disruptions in the production line. Let's dive deeper into how they stack up against other materials and why they're favored by many in the automotive industry. This isn't just about cost—it's about transforming the way we think about efficiency and reliability in manufacturing.

Steel wire ropes reduce maintenance costs by 20%.True

Steel wire ropes lower operational expenses by reducing downtime.

Steel wire ropes have a lower upfront cost than alternatives.False

The initial investment in steel wire ropes is higher than alternatives.

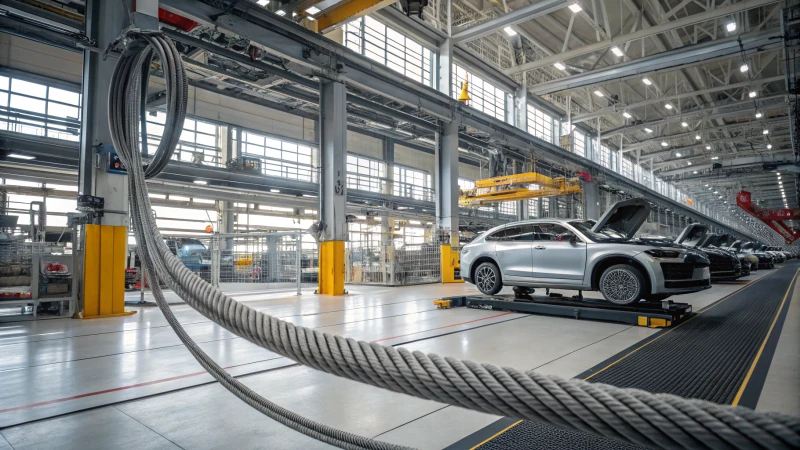

Why Choose Steel Wire Rope Over Chains in Automotive Manufacturing?

Have you ever wondered why steel wire ropes are often favored over chains in the world of automotive manufacturing? It's a choice driven by some compelling benefits worth exploring.

Steel wire ropes offer an outstanding strength-to-weight ratio, flexibility, and durability, making them superior to chains for automotive manufacturing. They significantly reduce operational costs by minimizing maintenance and downtime, enhancing efficiency in production processes.

Strength and Flexibility: The Winning Combination

Imagine lifting a load with ease because your materials are both strong and light. Steel wire ropes boast a remarkable strength-to-weight ratio1, unlike the hefty chains that can weigh down your operations. I recall the first time I witnessed a shift from chains to these ropes; the crew's relief was palpable as handling and installation became a breeze, cutting labor costs and boosting productivity.

Durability and Longevity

It's like investing in a sturdy pair of work boots that never seem to wear out. Steel wire ropes are built to last, resisting wear, corrosion, and fatigue. In my experience, choosing these ropes over chains saved us significant time and money—less frequent replacements meant fewer headaches. A study in the International Journal of Industrial Engineering even backs this up, showing potential savings of 20% on operational costs when opting for high-quality steel wire ropes.

Performance in Extreme Conditions

Picture this: you're working in an environment where the heat is intense, and chemicals are everywhere. Here, steel wire ropes shine bright, designed to endure such extremes without losing their integrity. Unlike chains, which might buckle under similar stress, these ropes keep your operations safe and reliable, even when the going gets tough.

| Property | Steel Wire Rope | Chains |

|---|---|---|

| Strength-to-Weight | High | Moderate |

| Flexibility | Excellent | Limited |

| Durability | High (resistant to wear and corrosion) | Lower (prone to wear and rust) |

| Maintenance | Low (infrequent needs) | High (frequent checks required) |

| Performance | Reliable in extreme conditions | Less reliable under stress |

Cost-Effectiveness

Remember that feeling when you realize the upfront cost was worth every penny? That's the case with steel wire ropes. While initially more expensive than chains, they prove their worth over time by slashing downtime and maintenance expenses. For folks like John and Emma, who need dependable solutions that pay off in the long run, these ropes are a strategic investment.

Industry Standards and Safety

In an industry where safety is king, steel wire ropes meet rigorous industry standards2, giving you peace of mind about compliance and quality. I know suppliers like WonBon who ensure their products are tested and certified, which is a huge relief when you're responsible for meeting safety regulations.

When you weigh all these factors, steel wire ropes clearly stand out as a versatile and practical choice for automotive manufacturing. Their enhanced performance, durability, and cost savings make them an attractive option for anyone serious about optimizing their manufacturing processes.

Steel wire ropes have a higher strength-to-weight ratio than chains.True

Steel wire ropes offer high tensile strength while being lightweight, unlike chains.

Chains are more cost-effective than steel wire ropes in the long run.False

Steel wire ropes require less maintenance, saving up to 20% on operational costs.

How do steel wire ropes enhance operational efficiency?

Ever wondered why steel wire ropes are indispensable in industries like construction and mining? Let me share my insights.

Steel wire ropes boost operational efficiency by ensuring durability, minimizing maintenance costs, and delivering safe, reliable performance in demanding environments. They play a crucial role in sectors like construction, mining, and logistics, where strength and reliability are paramount.

The Role of Steel Wire Rope in Reducing Downtime

Let me take you back to when I first realized the true value of steel wire ropes in construction. Picture this: a bustling site, everything is synchronized like clockwork, and then—boom—equipment failure. The entire project is halted. It’s moments like these that underscore the importance of reliable materials. Steel wire ropes come to the rescue with their incredible tensile strength and resistance to wear. In industries like construction3 and mining, they significantly reduce unscheduled downtimes, keeping productivity on track.

Enhancing Safety with Quality Steel Wire Rope

Safety isn’t just a priority—it’s a necessity. I remember an incident where a subpar rope snapped during a heavy lift, leading to a near-miss accident. It was a wake-up call for us all. High-quality steel wire ropes meet stringent safety standards and are designed to withstand extreme conditions and loads, particularly in mining operations where safety can never be compromised.

| Industry | Key Benefit of Steel Wire Rope |

|---|---|

| Construction | Enhances lifting capacity, meeting regulatory standards |

| Mining | Withstands extreme conditions for reliable performance |

| Logistics | Ensures secure transport of heavy goods |

Cost Efficiency Through Longevity

Initially, I was hesitant about the cost of high-quality ropes, thinking it was just another expense. But then I calculated the cost of frequent replacements of cheaper alternatives. The savings from fewer replacements and less downtime were undeniable. Investing in robust ropes not only lowers maintenance expenses4 but also enhances operational efficiency over time.

Versatility Across Applications

The versatility of steel wire ropes is something I’ve come to appreciate deeply. Whether it's cranes or elevators, these ropes adapt seamlessly to various applications, making them an invaluable asset for enhancing processes efficiency5 across diverse industries.

Reflecting on these aspects, it’s clear how steel wire ropes significantly contribute to operational efficiency. They ensure uninterrupted operations, safeguard our team, and offer a cost-effective solution through their extended lifespan. It's vital to understand these benefits when choosing the right product for your specific needs.

Steel wire ropes reduce downtime in mining operations.True

Their high tensile strength and wear resistance minimize equipment failures.

Steel wire ropes increase initial costs but save money long-term.True

Durability reduces frequent replacements, lowering maintenance expenses over time.

Why are steel wire ropes advantageous for long-term maintenance?

I remember the first time I saw a steel wire rope in action, its resilience and strength were immediately obvious. But what makes these ropes a wise long-term investment? Let’s explore how their maintenance benefits lead to cost savings and efficiency.

Steel wire ropes provide lasting maintenance advantages like reduced downtime, less frequent replacements, and superior durability. This translates into cost savings and enhanced efficiency, making them ideal for demanding industries such as construction and mining.

Durability and Longevity

The first time I realized the true value of steel wire ropes was during a construction project where the ropes had to endure extreme weather conditions. Their durability is incredible. Steel wire ropes are engineered to withstand tough environments, significantly reducing the need for frequent replacements. Industries like mining6 and construction7 benefit immensely from this longevity. It's not just about the ropes lasting longer; it's about them saving you money. According to a study in the International Journal of Industrial Engineering, using high-quality steel wire ropes can cut operational costs by up to 20% because of their extended lifespan.

| Feature | Benefit |

|---|---|

| High tensile strength | Reduced wear and tear |

| Corrosion resistance | Longer service life |

| Flexibility | Versatility in use |

Reduced Downtime

I once faced a critical deadline on a construction site where every minute counted. The reliability of steel wire ropes helped keep everything on track, reducing machine downtime significantly. Their dependability ensures smooth machinery operations, which is a godsend for procurement managers8 like me who have tight schedules to maintain. Knowing that equipment is less likely to fail boosts team morale and keeps productivity high.

Maintenance Cost Savings

Initially, investing in high-quality steel wire ropes might feel like a splurge, but trust me, the savings are real. With fewer replacements and repairs needed, resources can be allocated more effectively elsewhere. Plus, these steel wire ropes9 require minimal maintenance—just regular inspections and lubrication. This simplicity is a big relief, especially in industries where labor costs are high.

Enhanced Safety and Performance

Safety isn't just a priority; it's non-negotiable. Steel wire ropes offer outstanding safety features, minimizing risks of accidents due to material failure. Their performance under pressure maintains safety standards, which is why they're favored in sectors prioritizing safety. Using steel wire ropes10 means fewer workplace incidents and a safer environment overall.

Environmental Impact Considerations

If sustainability is important to you, as it is to me, you'll appreciate that steel wire ropes made from sustainable materials fit right in with eco-friendly goals. Their durability results in less waste over time—perfect for companies aiming to reduce their carbon footprint while maintaining quality and performance.

By grasping these maintenance benefits, we can make informed decisions on integrating steel wire ropes into our operations, striking a balance between cost-effectiveness and performance.

Steel wire ropes reduce machine downtime significantly.True

Steel wire ropes are reliable, minimizing machinery interruptions and enhancing productivity.

High-quality steel wire ropes increase operational costs by 20%.False

They actually save up to 20% on operational costs due to their durability.

How Can Steel Wire Rope Boost Safety in Manufacturing?

When I first stepped into the bustling world of manufacturing, safety was a top priority. That's when I discovered the unsung hero: steel wire rope. Can it truly elevate safety standards?

Absolutely, steel wire rope can dramatically enhance safety standards in manufacturing. It offers dependable support for lifting tasks, minimizes equipment failures, and significantly reduces workplace accidents.

Understanding the Role of Steel Wire Rope in Manufacturing

In my early days in manufacturing, I quickly realized the critical role that steel wire ropes play. They’re not just cables—they’re lifelines for hoisting, lifting, and securing hefty loads. Unlike synthetic fibers, steel wire ropes are robust and resilient, making them my go-to choice when heavy-duty performance is essential.

How Steel Wire Rope Enhances Safety

- High Load Capacity: I once oversaw a project where a single steel wire rope supported an immense load without a hitch. Its ability to withstand such pressure without deforming is invaluable, ensuring safe operations without the looming fear of mechanical failure.

- Durability and Longevity: These ropes are like the reliable old friend you can always count on. They endure wear and tear with grace, meaning fewer replacements and lower maintenance costs—something I’ve appreciated on tight budgets.

- Resistance to Environmental Factors: In varying conditions, from freezing cold to sweltering heat, steel wire ropes have proven their mettle by resisting corrosion and maintaining performance—attributes I’ve seen save the day in more than one project.

- Compliance with Safety Standards: Knowing that many steel wire ropes meet rigorous safety standards11 like those of OSHA and ISO gives me peace of mind. They’re a perfect fit for high-stakes applications where safety is non-negotiable.

| Features | Steel Wire Rope | Synthetic Fibers |

|---|---|---|

| Load Capacity | High | Moderate |

| Resistance to Heat | Excellent | Poor |

| Longevity | Long-lasting | Short |

| Environmental Impact | Recyclable | Non-recyclable |

Real-World Impacts of Steel Wire Rope Use

Case Study: Automotive Manufacturing

I recall reading a fascinating study in the International Journal of Industrial Engineering about automotive manufacturing. It highlighted how high-quality steel wire ropes not only enhance safety but also boost operational efficiency12. By slashing downtime, these ropes can save up to 20% on operational costs—a statistic that caught my attention as a procurement officer always looking to optimize.

Insights from Industry Experts

I often chat with peers like John from the construction sector, who emphasizes the necessity of partnering with reliable suppliers13. It’s not just about uninterrupted operations; it’s about building trust and long-term relationships that drive success.

Investing in robust steel wire ropes is more than a compliance measure—it’s a strategic move toward enhanced performance and fewer disruptions in manufacturing processes. Whether in construction, mining, or heavy machinery sectors, prioritizing quality in these essential tools pays off in both safety and efficiency.

Steel wire ropes have a high load capacity.True

Steel wire ropes are designed to handle immense loads without deforming.

Synthetic fibers outperform steel ropes in durability.False

Steel wire ropes are more durable and last longer than synthetic fibers.

Conclusion

Steel wire ropes enhance automotive manufacturing by reducing downtime and maintenance costs, offering a robust strength-to-weight ratio, and ensuring safety compliance, ultimately saving up to 20% on operational expenses.

-

Explore why materials with a high strength-to-weight ratio are crucial in manufacturing for efficiency and performance. ↩

-

Discover the specific safety standards that steel wire ropes must meet in automotive manufacturing contexts. ↩

-

Learn about how steel wire ropes enhance lifting capacity and meet industry standards. ↩

-

Explore how investing in quality steel wire ropes can reduce maintenance costs. ↩

-

Discover the various applications of steel wire ropes that enhance process efficiency. ↩

-

Explores how steel wire ropes benefit mining operations by enhancing durability and performance in extreme conditions. ↩

-

Details the advantages of steel wire ropes in construction, focusing on durability and efficiency. ↩

-

Provides insights into how procurement managers select durable materials like steel wire ropes. ↩

-

Covers effective maintenance strategies that prolong the life of steel wire ropes. ↩

-

Discusses how steel wire ropes contribute to enhanced safety standards in industrial applications. ↩

-

This link will clarify OSHA guidelines, ensuring compliance and improving workplace safety standards. ↩

-

Discover how steel wire rope reduces costs and enhances safety in automotive manufacturing through this link. ↩

-

Learn about suppliers who meet high safety standards, essential for building trust and long-term partnerships. ↩